This article throws light upon the four main considerations to be kept in mind for increasing the productivity of resources. The considerations are: 1. Material 2. Labour 3. Plant, Equipment and Machinery 4. Land and Buildings.

Consideration # 1. Material:

Industries in which the cost of raw material is a big percentage of the cost of finished goods, higher productivity can be achieved through proper use of materials, i.e., by reducing scrap. Sometimes a little change in the design of the component or component layout may save a lot of material.

Productivity of materials can also be increased by using correct process, properly trained workers, suitable material handling and storage facilities and proper packaging. All these factors reduce scrap rate.

Consideration # 2. Labour:

A little change in the design of component parts so as to facilitate final assembly, can increase the number of products assembled per day with the same amount of labour.

ADVERTISEMENTS:

Work methods if improved through work study techniques, can substantially increase the rate of production.

Consideration # 3. Plant, Equipment and Machinery:

Productivity Can be increased through the use of improved tools (e.g., cutting tools in a machine shop), simple attachments and other devices. Total production times can be cut short considerably by improving machine setting up methods, thereby reducing set-up times. Proper maintenance will (avoid sudden breakdown and) add to the productivity.

Consideration # 4. Land and Buildings:

A suitable plant layout can accommodate more machinery in the same space and thus raise productivity. Proper orientation, construction and inside conditions of a building definitely affect productivity.

Example:

ADVERTISEMENTS:

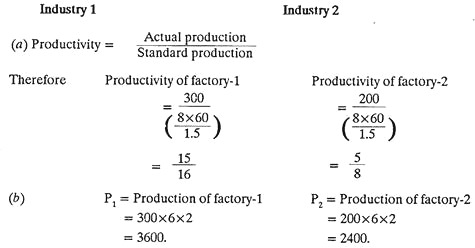

There are two industries manufacturing two types of plugs. The standard time per piece is 1.5 minutes. The output of the two industries is 300 and 200 respectively per shift of 8 hours.

(a) What is the productivity of each per shift of 8 hours?

(b) What is the production of each per week (6 days) on the basis of double shift?

Solution:

Practices advocated to improve worker’s productivity:

(i) Have shorter 3 or 4 day workweeks by lengthening shifts to 10 to 13 hours.

(ii) Tie wages more closely to output and use merit awards.

(iii) Develop and utilize more standard times in service industries.

ADVERTISEMENTS:

(iv) Redesign the content of jobs to make them more interesting and challenging.

(v) Improve communications to encourage everyone to work toward the same desired objectives.