One of the most important phases of plant layout is to achieve an optimum effective flow of materials (raw materials, and in-process materials) through the plant. Naturally the principle of minimum movements (i.e., number of movements and distance travelled in one move) forms the basis for optimum effective flow.

The principle of minimum movements reduces material handling costs, in- process inventory and space for processing. The supervision and control becomes simpler. While designing a new plant layout, generally the flow patterns are decided earlier and then a system of facilities (machinery, material and building, etc.,) is designed and built around the flow pattern.

As far as possible a flow pattern should be simple in order to have easy supervision and control.

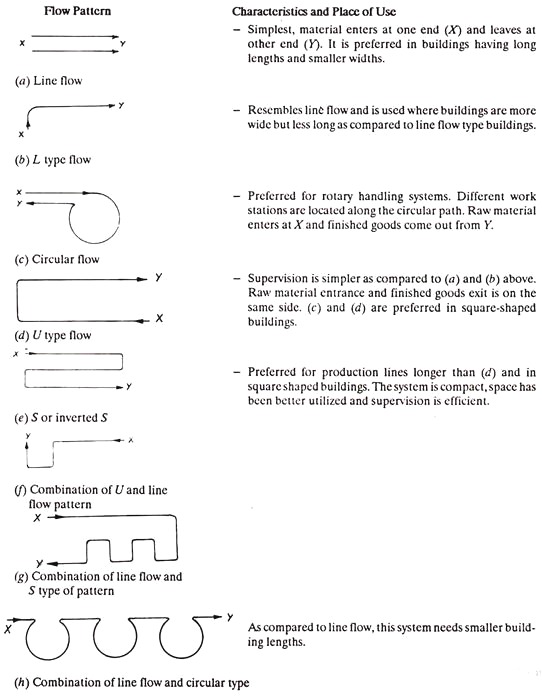

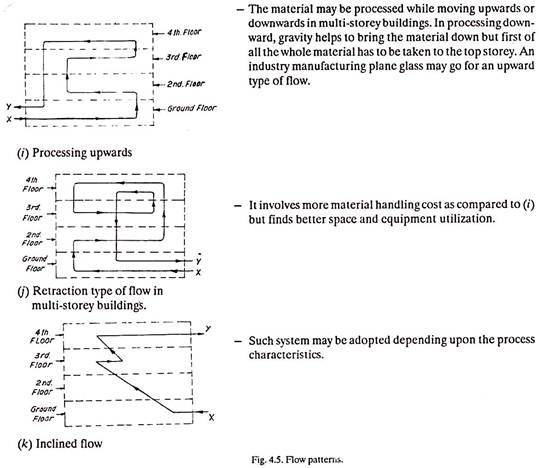

Various flow patterns along with their characteristics and place of application or use are given below: