After reading this article you will learn about the classification of materials used for handling of materials: 1. Lifting and Lowering Devices 2. Transporting Devices. 3. Combination Devices.

1. Lifting and Lowering Devices:

In this, all those handling devices are dealt which has only vertical motion.

(a) Block and Tackle:

Fig. 35.1 shows a Block and Tackle arrangement of lifting loads through a vertical distance. This is one of the oldest and simplest devices. It is still used today by moving men and in hoisting machinery into position. It depends in general on manpower and gives only the mechanical advantage that is possible for the various rope formations. It is the most inexpensive in cost but the most wasteful of manpower.

(b) Winch:

Fig. 35.2 shows a winch. This is used to lift loads vertically by winding the rope or cable on a drum. Here, it is possible to use manpower or other power, to get a much greater mechanical advantage than that with a Block and Tackle. It is frequently used in loading heavy equipment into ships, construction of buildings and in similar jobs.

(c) Power Hoist:

ADVERTISEMENTS:

Fig. 35.3 shows a power hoist, which is often operated between fixed guide rails, for lifting things vertically. There is an infinite variety of hoists suitable for different purposes. The simplest is the chain hoist, which is operated by hand. There are also hoists operated by compressed air or by electric power. The hoists are smaller to elevators except that a hoist does not carry the operator in it but is operated from one or two other points.

(d) Elevators:

Fig. 35.4 shows an elevator, hydraulic type. This is differentiated from hoists by the fact that the operator rides with the load. Although there are many different types of drives for such elevators, in general the only important type is the electric one. Hydraulic elevators arc now used only where it is dangerous to take the chance of an electric spark, as in acetylene generator houses.

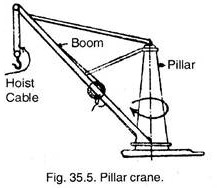

(e) Pillar Crane:

A pillar crane is shown in Fig. 35.5. This may be a stationary or mobile type. It is used for light duty and for lifting loads upto 20 tonnes. A jib or inclined boom is fixed to lift up or lower down the load with the help of rope and pulley arrangement. All the movements to the crane are provided by gearing and electric motor drive.

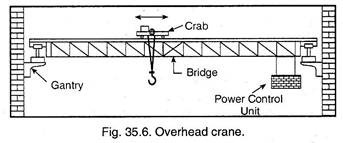

(f) Overhead crane:

ADVERTISEMENTS:

Fig. 35.6 shows an overhead travelling crane. Today all the big workshops such as Foundry, Power House, Chemical Plants, big repairing shops etc. have these cranes.

These cranes have the advantage of providing large service area and freedom from obstruction on the floor. In these all the movements are controlled by the driver seated in the cabin.

2. Transporting Devices:

Under this type, those devices which allow horizontal motion are dealt.

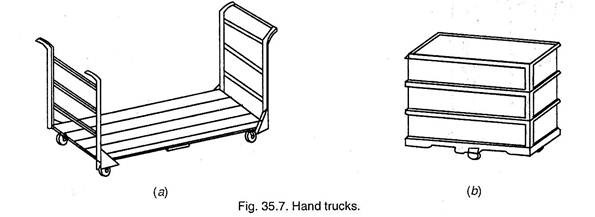

(a) Wheel Barrows and Hand Trucks:

The simplest transporting devices are wheel barrows and hand trucks. These are still in use by a number of small industries all over the country. Fig. 35.7 (a) shows a Hand truck, while Fig. 35.7 (b) shows a wheeler used to carry material inside the shops.

All such equipment’s involve a large amount of manpower for a relatively small load. The chief advantages of this equipment are its very low cost, great flexibility and easy portability from one job to another.

(b) Narrow-gauge Rail road:

ADVERTISEMENTS:

In general, little use is made of such equipment because it requires a heavy investment in the roadbed and tracks has little flexibility and is difficult to change at a later date. These were used in the days before the development of rubber-tier equipment. They are still found in metal-working industries (blast furnaces, copper refineries and steel-rolling operations) and in mining activities, where it is cheaper or more desirable to lay tracks than to pave the entire area.

(c) Tractors and Trailers:

These are one of the most common methods of horizontal transportation. Great flexibility is achieved as tractors can be used to haul such a variety of different types of trailers. Trailers can be lift-loaded and can be picked up by different tractors.

This system has the advantage of great flexibility plus all the advantages of industrial railways and there is no investment in laying tracks. This is one of the most important methods of handling materials inside the plant and from one building to another.

ADVERTISEMENTS:

(d) Railway Equipment:

Where plants are located at a considerable distance and the items handled are extremely large, such as in some steel-rolling operations, the use of actual railway equipment is advantageous.

(e) Aerial Tramways:

This is also a horizontal transportation system in which the load carrying vehicle is supported from the top usually by means of a cable or its equivalent.

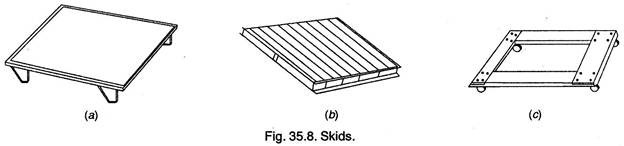

(f) Skids:

These are shown in Fig. 35.8 and Eire used with lifts trucks. Goods may be loaded into skids and then picked up with lift trucks. The skid can be loaded as a unit and transferred from position to position without subsequent loading and unloading. Both skids and pallets raise the load off the supporting surface and allow the easy insertion of the conveying means.

Some materials are stored on dollies Fig. 35.8 (c). This can be moved on their casters. Other material is stored on skids. The most common skids, which can be picked up in either direction, consist of a wooden platform and four steel legs.

(g) Pipe Line:

Pipe lines and pumps are also used for horizontal transportation of commodities. Most obvious among these is oil, which is pumped at great distance through pipe line. Natural gas is also carried through pipe lines. Water is similarly transported.

3. Combination Devices:

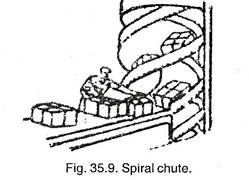

(a) Chute:

One of the simplest devices that have both vertical and horizontal motion is a chute which may either be straight or spiral (Fig. 35.9). In this, gravity is utilized to move the material. Chutes are common in railways and air-line terminal for handling package and baggage.

(b) Lift Truck:

ADVERTISEMENTS:

The lifting feature in lift trucks provides clearance from the floor for the skids and permits horizontal transportation.

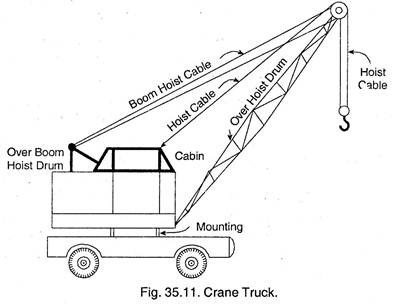

(c) Crane Truck:

Small crane trucks (Fig. 35.11) operate on the same principle as lift trucks. They are used for materials that cannot be put on skids or not available for skids at the present time or too much heavy to handle in the lift trucks. This moves quickly over smooth, even and hard ground. This can be carried at will to any place. In these cranes, the solid rubber tyres are used. The cranes are revolving type so that the load can be lifted from any position.

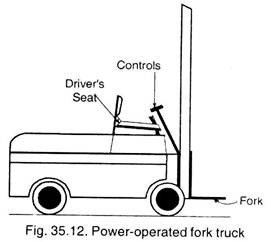

(d) Fork Truck:

ADVERTISEMENTS:

Fork trucks need no particular explanation except for the development of tail board called for, which will receive the load at ground level and elevate it to the level of the truck so that all manual lifting is avoided (Fig. 35.12).

When the load is to be shifted from one shop to another fork trucks are used. These trucks do not require any extra man, and driver operating the truck can also lift, carry and unload the materials. Self-loading and unloading can be carried out by providing fork at the front end of the truck.

(e) Conveyors:

If the path for the flow to material is fixed then the provision of the conveyors at suitable levels eliminates a good deal of lifting and lowering of materials. Conveyors require no stopping or starting but are continuous in operation.

ADVERTISEMENTS:

In these, transportation is affected by friction between materials being transported and the belt. These conveyors have the advantage that they largely save labour cost, but have disadvantage that take up considerable space, are relatively fixed and in most cases the investment cost is high.

There are several kinds of conveyors, such as:

(i) Belt conveyor,

(ii) Elevating conveyor,

(iii) Roller conveyor,

(iv) Chain or cable conveyor,

ADVERTISEMENTS:

(v) Pipe line conveyor, and

(vi) Screw conveyor.

Each type is explained in short below:

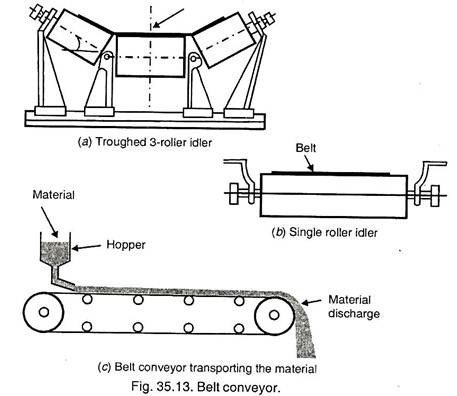

(i) Belt conveyor:

Fig. 35.13 shows a belt conveyor, which consists of moving endless belt and carries materials within supporting frames. This has a power driven pulley at one end which moves the belt. Belt is made from rubber fabric or leather.

This conveyor is mostly used for handling large quantities of material such as cement, fertilizer, coal, ore and other similar materials.

(ii) Elevating conveyor:

This is used for transporting dry granular materials in the vertical direction with the help of buckets and trays.

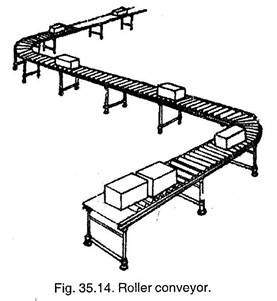

(iii) Roller conveyor:

Fig. 35.14 shows this type of equipment. This is used to transport products of various shapes such as boxes or material which extend over several rollers. This type consists of roller supported in frames over which materials are allowed to move. They are driven by power or gravity. These are of different varieties and can move materials in horizontal direction as well as from the upper floor to lower floor etc.

(iv) Cable conveyor:

This is moved by chains or cables in horizontal direction and installed flush with floor or a little above it. This is used for moving barrels and heavy boxes. This is also used for moving grates of big boilers.

(v) Pipe line conveyor:

This is largely used for transporting dry, pulverized or granular materials, chemical powder, sand, cement etc. It can be operated by gravity, air pressure or some mechanical means.

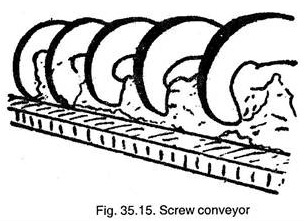

(vi) Screw conveyor:

This type is used for transmitting materials in the paste or powder form with the application of rotating screw.

Fig. 35.15 shows an example of feeding pulverized coal into a furnace.

(f) Positioning equipment:

These are equipment’s used to give the correct position to materials during process. For example: dumpers, tripplers, manipulators etc.

(g) Marine vehicles:

These are mostly used in marine such as lake vessels, river and canal boats.

(h) Air transport:

It includes all types of aircraft.