After reading this article you will learn about the requirements of product design and factors affecting it.

Requirements (or Considerations) of a Good Product Design:

It is not possible to specify exactly what constitutes a good design, but the essential requirements are that it should bring:

(a) In order to achieve customer satisfaction:

The product should function correctly. It should possess desired degree of accuracy. It should have required standard of reliability. Product should be easy to operate e.g., a number of controls may be operated from one position. Product design should be such that it is easy to achieve accessibility for servicing.

ADVERTISEMENTS:

Product design should obtain good space utilization. Product should be sufficiently rugged to withstand all but exceptionally rough handling. Product should have pleasant appearance. Colours play an important role in product design. Product should be of reasonable price to compete other products in the consumer market.

(b) Making adequate profit means that:

It should be easy to manufacture the product within the available resources. Manufacturing process should be decided on the basis of the product quantity to be manufactured. Small parts on mass scale may be produced by the casting rather than the sand casting.

The use of standard component parts wherever possible can lead to great saving. A well designed product will consist of minimum number of parts. Good product design will call for minimum number of operations. Good product design should not extend the through-put time. A well designed product should be easy to pack and distribute.

Factors Affecting Product Design:

ADVERTISEMENTS:

The design of any product involves due attention to the following factors:

(a) Technical factors:

1. Operating conditions:

i. Kind of workers which will be making use of the product.

ADVERTISEMENTS:

ii. Conditions of noise, vibrations and heat, etc.

2. Performance:

i. Accuracy.

ii. Speed, feed, etc.

ADVERTISEMENTS:

iii. Length of time.

iv. Type of materials used.

3. Maintenance:

i. How often maintenance and repair will be required.

ADVERTISEMENTS:

ii. Whether planned or breakdown (maintenance) policy will be adopted.

4. Company experience:

i. Has the product been designed by the company before?

ii. Has the company experience or expertise to design the product?

ADVERTISEMENTS:

(b) Industrial design factors:

1. Function:

Will the product function at minimum cost?

2. Appearance:

ADVERTISEMENTS:

i. Does the product has a pleasing appearance?

ii. Does it create esteem?

3. Ergonomics:

i. Is the product suitable for human use?

ii. Does the use of product cause excessive fatigue to the workers?

iii. Does the product fulfills the principles of ‘Fitting the job to the workers’?

ADVERTISEMENTS:

(c) Designing for production-economic factors:

1. Materials:

i. Material specifications:

Is the cheapest material, consistent with technical design requirements, being used.

ii. Yield:

Is the waste during production being minimized?

ADVERTISEMENTS:

iii. Content:

Is the minimum amount of material being used in making each component part?

2. Methods:

i. Equipment:

For the production quantity required, can the most productive equipment be employed?

ii. Layout:

ADVERTISEMENTS:

Does the product design make best use of factory layout?

iii. Labour:

Can the product be manufactured with the available (direct and indirect) labour?

iv. Tolerance:

Does the product design allow the maximum possible tolerance?

v. Tooling:

ADVERTISEMENTS:

Does the product design permit the use of existing or otherwise simple economical tooling?

vi. Overheads involved.

3. Standards:

i. Is design simple?

ii. Does it keep (number of) types and varieties of parts to a minimum?

iii. Does the design make use of standard parts?

ADVERTISEMENTS:

4. Finish:

i. Finish may include painting, polishing, electroplating, etc.

ii. Is the right finish being used consistent with cost, endurance and appearance requirements?

Product Design by Imitation:

New designs come from innovation. New conceived ideas are developed and turned into new products. But, this procedure involves a lot of money and risk of failure or unsuccessful in the consumer market. For this reason, the greatest flow of new designs is not from innovation but by imitation.

Design by imitation saves a lot of R & D money and avoids the risk of being unsuccessful; because only those designs are imitated which have proved their success in the market. Imitators start late but move faster than the innovators since they can easily get the new product and its design. For example, in 1950’s, Sperry Rand had the first computer but IBM soon captured the market and is very well known today for its computers.

Product Design Specifications and Drawings:

A designer communicates his ideas to the manufacturing section through the medium of drawings and specifications.

Preparation of drawings and specifications is the last step in product design.

Drawings:

Drawings show the exact size and shape of the product, its different parts and subassemblies. Rough sketches made during the process of product designing are drafted into exact engineering drawings. Drawings show, how the finished parts, subassemblies and the final product look like when completed. Drawings are generally made on standard-sized drawing sheets in order to facilitate their storage, filing and reproduction. A drawing should be kept as simple as possible and be clearly drawn. An ambiguity on a drawing can lead to mistakes.

An engineering drawing should include the following information:

(i) Component part number (for identification) and part description,

(ii) Dimensions from a common datum face to facilitate setting and gauging,

(iii) Tolerances and limits,

(iv) Material details including specification, size and condition,

(v) Finish description,

(vi) Title block,

(vii) Scale and projection, and

(viii) Details of any inspection requirements.

Before releasing drawings to the manufacturing section, they should be checked, approved by the persons concerned and given the date of issue.

Specifications (bill of material or parts list):

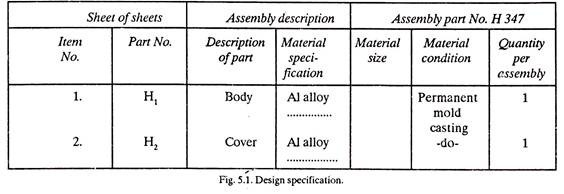

Product design features other than physical dimensions (already shown on the drawings) are described in writing in the form of specifications. The specification is regarded as the key manufacturing document. Industries producing single-unit articles such as forgings and castings can provide all the relevant information on the drawings, but those industries which make assemblies need a complete/ram list to assist in buying, production control and assembly. Specifications provide a written statement of requirements. It states the function of the product. A typical specification is shown in Fig. 5.1.

In addition, the specifications may include the following:

(i) Conditions of testing (i.e., range of temperature, vibrations, humidity, etc.),

(ii) Efficiency of performance,

(iii) Site testing and commissioning procedure, and

(iv) Quality of material and finish, etc.