Logistics management is one of the time and cost saving strategies of business organizations. It is now being related to supply chain management.

Supply chain has become important to companies to gain competitive advantage in terms of speed and cost of delivery of products and services to customers. Marketers therefore should have a good understanding of the goals of logistics and value chains.

Logistics management is conventionally defined as the process that has the responsibility to ensure the delivery of the right product at the right place at the right time in right quantities.

Normally, when logistics management is talked about, the entire supply chain is considered, from the raw material procurement stage to the delivery of finished goods to the customers.

Learn about: 1. What is Logistics Management 2. Definition of Logistic Management 3. Objectives 4. Major Activities Involved 5. Functions

6. Channel Strategy, 7. Logistics Mix, 8. Logistics Costs 9. Importance 10. Logistics Planning 11. Warehouses in Logistical Systems

12. Decisions Involved 13. Materials Management, Warehousing and Distribution 14. Strategic Issues 15. Impact 16. Role of Materials and Distribution Management 17. Strategy Building.

Logistics Management : What is Logistics Management, Meaning, Definition, Functions, Importance, Objectives, Logistics Planning and More…

What is Logistics Management (Meaning)

Logistics management is one of the time and cost saving strategies of business organizations. It is now being related to supply chain management. Supply chain has become important to companies to gain competitive advantage in terms of speed and cost of delivery of products and services to customers. Marketers therefore should have a good understanding of the goals of logistics and value chains.

Distribution can be analyzed into two aspects- physical distribution and channels of distribution. Physical distribution refers to the process of moving goods from factory to points of purchase by customers. It includes location of plants and warehousing, transportation mode, inventory and packing.

The systems concept of physical distribution establishes firm linkages among these component activities. It is called as an integrated market logistics that recognizes interdependence of costs of each activity. It involves activities that begin when the customer places the order and that end with the delivery of the product to the customer.

The main elements are:

i. Order processing

ii. Warehousing

iii. Inventory

iv. Transportation.

Recently, the concept of integrated market logistics system is referred to as supply chain management, which is broader in its scope. It is concerned with all the flows starting from supplier to manufacturer to customer. As such integrated market logistics system is a subset of supply chain management of a firm.

Physical distribution starts at the factory. Managers choose a set of stocking points (warehouses) and transportation carriers that will deliver goods to final destinations in the desired time and at the lowest total cost. Physical distribution has now been expanded into the border concept of supply chain management (SCM). Supply chain management starts before physical distribution.

It involves procuring the right inputs-raw materials, components and equipments; convert them into finished products and dispatching them to the final destinations. Therefore logistics management involves two distinct and integrated functions. One is of materials management and the other is physical distribution management.

The focus of logistic management is on removing inefficiencies and blocks in fulfilling customer demand in real time. This obviously requires- (i) Material Planning (ii) Inventory Management (iii) Management of Transportation (iv) Management of warehouse and (v) Management of Information.

Logistics can be divided into- (1) Inbound Logistics and (2) Outbound Logistics. Inbound logistics is concerned with efficient acquisition, delivery, control and application all inputs, finished or semi finished goods and services used for the internal operation of the firm. This obviously involves operations of transport, warehousing and vender management.

Forecasting demand for raw materials and other inputs is the key to materials planning. This projection is possible only when there is a proper market projection. Outbound logistics is concerned with the physical distribution of products, services and information from the firm to the customer through a defined network of transportation links.

For the successful functioning of logistics channel integration is the key element. In order to achieve channel integration, firm must design and implement a logistics system that coordinates the different parts of the entire distribution system so as to enhance customer value at the lowest cost.

Information systems play a vital role in managing logistics. Information systems have helped organizations to shorten the order-cycle time, reduced clerical labour, reduced error rate in documentation and improved control of operation.

Logistics Management – Definitions

The Council of Supply Chain Management Professionals, US, defines logistics management as ‘part of supply chain management that plans, implements, and controls the efficient, effective, forward and reverse flow and storage of goods, services and related information, between the point of origin and the point of consumption in order to meet customers’ requirements’.

The definition of logistics- ‘Logistics is customer- oriented operations management’. This would then include all the functions required for distribution of goods.

The term logistics comes from the late 19th century- from French ‘logistique’, from ‘loger’ meaning ‘to lodge’.

Logistics is considered to have originated in the military’s need to supply itself with arms, ammunition, and rations as it moved from a base to a forward position. In the ancient Greek, Roman, and Byzantine Empires, military officers with the title Logistikas were responsible for financial and supply distribution matters.

The Oxford English Dictionary defines logistics as “the branch of military science relating to procuring, maintaining and transporting material, personnel and facilities.”

However, the New Oxford American Dictionary defines logistics as “the detailed coordination of a complex operation involving many people, facilities, or supplies”, and the Oxford Dictionary online defines it as “the detailed organization and implementation of a complex operation”.

Another dictionary definition is “the time-related positioning of resources.” As such, logistics is commonly seen as a branch of engineering that creates “people systems” rather than “machine systems”.

According to the Council of Logistics Management, logistics includes the integrated planning, control, realization, and monitoring of all internal and network-wide material, part, and product flow, including the necessary information flow, in industrial and trading companies along the complete value- added chain (and product life cycle) for the purpose of conforming to customer requirements.

Hence from the above definitions it can be concluded that, Logistics is the process of planning, implementing, and controlling the effective and efficient flow of goods and services from the point of origin to the point of consumption.

Logistics is the thus the management of the flow of resources between the point of origin and the point of consumption in order to meet some requirements, of customers or corporations. The resources managed in logistics can include physical items, such as food, materials, equipment, liquids, and staff, as well as abstract items, such as time, information, particles, and energy.

The logistics of physical items usually involves the integration of information flow, material handling, production, packaging, inventory, transportation, warehousing, and often security. The complexity of logistics can be modeled, analyzed, visualized, and optimized by dedicated simulation software.

Distribution functions can be classified as exchange functions, logistical functions, and facilitating functions. The interesting point here is that the logistical functions are central to the distribution strategy. None of the exchange or facilitating functions could be performed without strong logistical functions. In fact, the other functions lose meaning if logistics are wanting in a company. For instance, none of the buying or selling could take place if goods are not made available when and where they are required.

Companies, therefore, invest in their logistics strategy to maintain their supply chain. Challenges exist at both domestic and global levels. At the local level, there are the challenges of lack of infrastructure, technology implementation, and lack of trained personnel.

Globally, there are challenges of greater distance, documentation, coordination, cultural and political differences, need for flexibility and speed, and green logistics. In, fact, the earthquake in Japan in 2011 has exposed a new challenge altogether – companies buying globally have to prepare for disruptions in the supply chain because of natural disasters occurring in the world.

The importance of logistics was realized by military science dealing with procuring and transporting materials and facilities. The art of winning wars involved moving huge numbers of men, material, rations, and equipment in a short time. Wars require great management inputs as the task is not merely sending armies to other countries, but also providing support structure for them and that too in enemy territory.

In business, logistics strategy gives an edge to companies. Companies are able to reduce costs considerably and speed up deliveries to customers. In some cases like that of Dell, logistics becomes crucial in differentiating the company from all others. In other cases, companies can tweak their logistics and streamline operations to ward-off competition and to involve dealers to provide better service.

A distribution channel usually comprises two complementary networks- the commercial network and the logistical network.

The commercial network takes care of the resources required for the efficient and effective operation of the logistical network. The logistical network is involved in the actual transportation of the goods and services from the place of manufacture to the place of consumption.

In India, the logistics costs are higher than in the developed markets—estimated to be around 13 per cent of the gross domestic product (GDP), against 9 per cent of the GDP in the US. The logistical function, since it is concerned with the physical movement of goods, is also called the physical distribution function.

Logistics management is conventionally defined as the process that has the responsibility to ensure the delivery of the right product at the right place at the right time in right quantities. Normally, when logistics management is talked about, the entire supply chain is considered, from the raw material procurement stage to the delivery of finished goods to the customers.

The Council of Logistics Management defines logistics in the following manner:

Logistics is the process of planning, implementing and controlling the efficient, cost-effective flow and storage of raw materials, in-process inventory, finished goods, and related information from the point of origin to the point of consumption for the purpose of conforming to customer requirements.

However, since we are limiting our focus to the logistical activities concerned with the distribution channels, we will only be concentrating on the second part of the chain, namely the delivery of the finished goods and services to the customers from the manufacturers’ end.

This part of the logistical activities of a firm is called the outbound logistics of the company. The outbound logistics is a critical activity in any firm as it directly links the company to its consumer and comprises a set of activities that complements the marketing function of the firm.

Further, the outbound logistics of a firm usually absorb significant resources of the firm both in terms of the financial resources as well as human resources. It is estimated that in the fast moving consumer goods (FMCG) sector, almost 40 per cent of the final cost that a customer pays is absorbed by logistical activities. Though the cost of logistics may vary from one industry to another, with improved coordination and efficient planning, it is possible for a company to reduce the expenditure on logistics.

Logistics Management – Objectives

The objective of physical distribution is getting the right goods to the right places at the right time for the least cost. Evidently, this involves a trade-off between customer service and cost.

The conflict in goals can be expressed as follows:

i. Maximum customer service implies large inventories, premium transportation and multiple warehouses all of which raise distribution cost.

ii. Minimum distribution cost implies cheap transportation, low stocks and few warehouses. Optimization of each of the components (subsystems), order processing, warehousing, inventory and transportation, may appear to be the right answer. But it is not correct. Physical distribution decisions must aim at optimization of total system and not the sub-optimization at the subsystem levels, i.e., order processing, warehousing, inventory and transportation.

1. Customer Service:

Marketers have to decide their service standards based on key information about customers and competitors.

(a) What the customers are looking for?

(b) What the competitors are offering?

Typical service standards are:

i. Put the product within an arms-length of customers.

ii. To deliver at least 95 per cent of the dealer’s orders within seven days of the receipt.

iii. To ensure that damage to merchandise in transit does not exceed 5 percent.

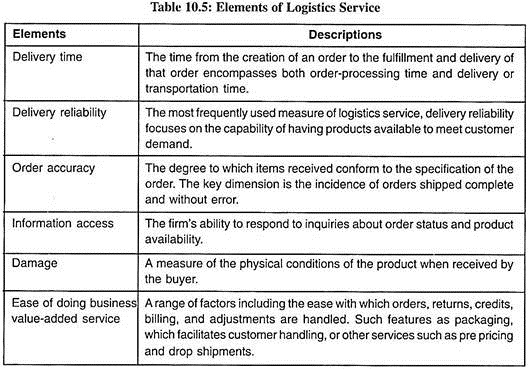

However, not all products or all customers require the same level of logistical service. Many business products that are made to order—such as heavy machinery—have relatively low logistical service requirements. Others, such as replacement parts, components, and subassemblies, require extremely demanding logistical performance. Similarly, customers may be more or less responsive to varying levels of logistical service. The Table 10.5 indicates the elements of logistic service.

2. Cost:

The next step is developing a cost function for a service level as shown below:

D = T + FW + VW + S

Where,

D = Total distribution cost of proposed system

T = Total freight cost

FW = Total fixed warehouse costs

VW = Total variable warehouse costs

S = Total cost of sales lost due to average delivery delay under proposed system.

The company should aim at minimizing the distribution cost of reaching a target level of customer service.

Key Decisions:

We will now examine the four major decision issues:

(1) How should orders be handled? (Order Processing)

(2) Where should stocks be located? (Warehousing)

(3) How much stock should be held? (Inventory)

(4) How should goods be shipped? (Transportation)

(a) Order Processing:

The first phase in physical distribution is order – shipping – billing cycle.

A customer order initiates several steps:

1. Order department prepares multi copy invoices and dispatches them to various departments.

2. Order is checked with available stock. Items out of stock are back ordered.

3. Items are shipped. Shipped items are accompanied by shipping and billing documents with copies going to various departments.

The whole process is now expedited with the help of computers by warehousing.

(b) Warehousing:

A storage function is necessary because the production will be more than customer orders in general. Striking a balance between customer service standards and distribution costs, marketers has to decide on a desirable number of stocking locations depending upon the markets the firm intends to serve.

Choose the type of warehouses- Today a variety of warehouses, with advanced material handling systems and storage facilities are available.

(c) Inventory:

Inventory management requires decisions relating to-

(1) Level of stock – Determining optimum order quantity

(2) Time of ordering – Reorder point

(3) Minimum stock level to meet emergencies – Safety Stock.

Today, just-in-time production practices and product customization are changing the inventory planning practices.

(d) Transportation:

Marketers have to make careful choice of transportation mode and organizations. In choosing a transportation mode for a particular product, shippers consider such criteria as-

i. Speed

ii. Frequency

iii. Dependability

iv. Capability

v. Availability

vi. Cost.

4 Main Activities Involved in Logistics Management

1. Transportation:

Transportation helps an organization to exploit market opportunities to a greater extent. In adequate transport services like non-availability of transport services, uncertain transit time etc. will hamper marketing activities.

The decision maker should consider the following factors while selecting transportation mode:

(i) Costs

(ii) Dependability of the mode

(iii) Transit loss and damage

(iv) Reach of the mode

(v) Speed at which firm is able to reach the market

2. Warehousing:

Organization may decide to own its own warehouse or can go for third party warehouses.

Whenever firm uses its own or a third party warehouse, it has to take following decisions:

(i) Number of warehouses and their location

(ii) Level of customer service required

(iii) Cost of distribution

(iv) Technology to be deployed- Automated or otherwise

3. Inventory Management:

Inventory level also impacts the competitive advantage of a firm. Here the marketer has to maintain a fine balance between stock outs and stockpiles. Many companies are trying to manage this function through (JIT) Just in Time process.

4. Third Party Logistics:

Today there are several third party logistics providers in the country. These firms specialize in the development and application of new and innovative methods of packing, handling, transportation and freight management.

Third party logistics are gaining importance for the following reasons:

(i) Due to their core competencies they are able to render better services

(ii) Internal system development costs and staffing costs are eliminated

(iii) They customize their services to meet the needs of their clients

(iv) They helps in controlling costs and improved customer services

While choosing a third party logistic, following aspects:

(i) Competency in approach, culture and attitude of the logistic organization

(ii) Quality of services to be provided

(iii) Experience in a particular line

(iv) Performance track record

(v) Flexibility

(vi) Financial muscle

(vii) Brand image

Thus, logistics decisions today are most complex and demand considerable time from the decision maker. Brand equity can be enhanced through a good logistics decision.

Broadly speaking promotion means to push forward or to advance an idea in such a way as to gain its acceptance and approval. Promotion is any communicative activity whose main object is to move forward a product, service or idea industries, a channel of distribution. It is an effort by a marketer to inform and persuade buyers to accept, resell, recommend, or use the article, service or idea which is being promoted.

Promotion is a form of communication with an additional element of persuasion. The promotional activities always attempt to affect knowledge, attitudes, preferences and behaviour of recipients, i.e., buyers. The element of persuasion to accept ideas, products, services, etc., is the heart of promotion.

In any exchange activity, communication is absolutely necessary. You may have the best product, package and so on. It may have fair price. But people may not buy your product, if they have never heard of it, and they are simply unaware of its existence. The marketer must communicate to his prospective buyers and provide them adequate information industries a persuasive language.

People must know that the right product is available at the right place and at the right price. This is the job of promotion in marketing. Sales do not take place automatically without promotion or marketing communication, even though our product is superb, it can precisely fill the consumer wants, and we have appropriate channels for distribution.

In essence, promotion is the spark plug in our marketing mix. It is said that? Nothing happens until somebody promotes something? Promotion is the third element of marketing mix and it is an important marketing strategy. It fulfills the marketers need to communicate with consumers.

4 Major Functions of Logistics Management

The major logistics functions include Warehousing, Inventory Management, transportation and logistics information management.

Let us take a look at each of these functions in detail:

Function # 1. Warehousing:

In most cases, one can see that the production of goods happens much earlier than their consumption. That is goods are first manufactured, then transported, stored, sold through channel members and then consumed. As such the production and consumption cycles are not in synchronisation with each other.

Owing to this it becomes necessary for the organisation to store the goods until the time that they are ready to be sold. Storage of goods helps organisations to overcome the differences in the needed quantity and the timing, ensuring that the products are available just when the consumers need them. It is here that organisations look at the warehousing function.

As a part of the warehousing function, organisations need to decide on how many and what type of warehouses it needs and where.

Types of Warehouses:

Generally organisations can opt for two types of warehouses.

They are:

i. Storage Warehouses – These are simple warehouses that engage only in storage of goods for moderate to long periods.

ii. Distribution Centres – These are warehouses that are designed to move goods rather than only store them. They are highly automated. The warehouse has inbuilt automated systems to receive goods from various suppliers, take orders, fill the orders and deliver the goods. As such they perform functions other than just storage of goods.

Function # 2. Inventory Management:

Inventory management involves maintaining sufficient inventory or stocks to suit the customer requirements. Here there is a trade-off between maintaining too little and too much inventory. With too little stock, there is a risk that the organisation may not have the desired goods when the customer needs it. On the other hand too much stock results in very high inventory carrying costs and stock obsolescence. As such both these aspects need to be delicately balanced.

Many organisations today have reduced their inventory carrying costs by adopting just- in-time logistics systems which enable the organisation to carry stocks for as little as 3 to 5 days of operations. New stock arrives just when needed, rather than being in the warehouse for a long time. This system however, requires accurate forecasting along with fast, frequent and flexible delivery schedules.

Organisations today are trying to look at new ways of making the inventory management system more efficient by leveraging technology. Use of RFID tags or smart tags embedded in the products has made tracking products very easy. Soon the entire supply chain will be automated and at any given point in time the organisation would be able to know where exactly a product is located, “Smart shelves” would not only prompt the time for re-order but also do the reordering automatically.

Function # 3. Transportation:

This is yet another important aspect of the Marketing Logistics function. Choice of the transportation carrier not only affects the final price of the product, but also determines the delivery performance and the condition of the goods on arrival ultimately affecting the customer satisfaction. In shipping goods the main modes of transportation that are available to the organisations include –

i. Road Transport.

ii. Rail Transport.

iii. Water Transport.

iv. Air Transport.

Many organisations also use intermodal transport systems, which is a combination of two or more modes of transport. Piggyback is the use of rail and trucks, fishy back (the use of water and trucks), train ship (water and rail), and air truck (air and truck) are all used together. Combining modes of transport helps organisations to maximise on the benefits offered by both the modes. While choosing the mode of transportation the organisation needs to look at speed of delivery, dependability, cost and availability.

Function # 4. Logistics Information Management:

Information is a vital aspect of logistics management. Information can be shared as well as managed through a number of sources like the email, telephone or even through electronic data interchange (EDI) which is the computerised exchange of data between organisations. Here the organisation is connected to the Suppliers through computer networks and change in the inventory levels of the organisation can be checked by the supplier who can then replenish the stocks. Many organisations have their suppliers to generate orders and arrange deliveries for their customers. Such systems are also known as Vendor Managed Inventory (VMI) system or Continuous Inventory Replenishment System.

Channel Strategy, Logistics Mix and Logistics Costs

Marketing mix consists of both the channel strategy and logistics management. While channel strategy consists of setting up and operating the infrastructure to serve customers, logistics management is concerned with product availability at the appropriate time and place in the marketing channel.

Channel strategy refers to the set of decisions that an organization makes to access and provide services to customers. Channel strategies can also provide organizations with the means to cope-up with the erosion of traditional sources of competitive advantage.

While channel strategy is concerned with the process of developing and operating the contractual organization, logistics management is focused specifically on providing product availability at the appropriate time and place.

This is an important element of strategy as the components of place are difficult to copy by competitors, while the other Ps can be emulated. Channel strategy does not merely deliver goods but informs the customers as well; it also helps in display and enhances the quality of goods and services. Channel strategy, thus, combines call centres, Internet, advertising and promotion with the delivery.

Channel strategy is important because a product or service is of little value if it is not available to customers when they want it. Customer ‘value’ is created when goods are moved from manufacturer to customer. This task is achieved through a good logistics mix.

Logistics Mix:

The task logistics management is initially concerned with is managing the components of the ‘logistics mix’.

It consists of five components:

i. Storage facilities – Warehouses, distribution centres, or stock rooms of retail stores. Adequate stock must be kept in stores to enable companies to meet the demand or to react to sudden spikes in demand.

ii. Inventory – Stocks are held by wholesalers and retailers. They must decide on the amount of stock that must be held for each product. More stocks represent blockage of working capital and the inventory holder incurs carrying cost.

iii. Transportation – The company, wholesaler, and retailer must decide on what mode of transport must be used for transporting goods.

iv. Packaging – Customers generally buy products in small quantities, making purchase decisions based on product presentation and packaging. Retailers want those products that are easy to handle in logistics terms, do not cost too much to package or handle, yet retain their selling ability on the shelves.

v. Communication – Information is needed about demand and supply, volumes, stock, prices, and movements. Retailers are increasingly concerned with the data available at appropriate points in the system and to use that information.

All these elements are interlinked. In the past they were often managed as separate functional areas or ‘silos’ but now the management approach is to integrate these logistics tasks.

One of the main objectives of logistics management is to keep costs under control. By introducing efficiencies, not only are costs reduced but the company also saves through reduction of errors. In some cases, companies may also tie up with competitors in order to share infrastructure and costs.

Logistics costs are firmly tied up with service standards. If the company wants to delight customers by providing very high standards of service, it has to incur high costs, which may be passed on to customers if they are willing to pay. For instance, quicker deliveries can be achieved by sending goods by airfreight, but this will considerably add to cost.

It is doubtful whether many customers will be happy to bear a high cost for quicker deliveries. Thus, companies must decide on the trade-off of higher costs and higher service standards. So, if customers do not wish to bear high costs, a company would be ill-advised to offer delivery guarantees. This aspect must be kept in mind while designing the logistics strategy.

This can be explained by the ‘tipping point’ between cost and service. Managers must achieve an appropriate balance between the two. Walters and Rainbird (2004) point out that if the system is too cost-focused then it may not meet the consumer demands, with dire business consequences. Conversely, too much focus on the consumer and the provision of too high service levels will cause cost problems.

Once the service levels have been decided, logistics can help bring down costs through better management techniques. Companies have realized that the powerful route to achieving cost advantage comes not necessarily through volume and the economies of scale but, instead, through logistics management. Since logistics costs represent a significant proportion of total costs, it is possible to make major cost reductions through fundamentally engineering logistics processes. In the following sections, transportation, warehousing and total costs are analysed.

i. Transport Costs:

Around one-third to two-thirds of the expenses of a company’s logistics costs is spent on transportation. In terms of costs, transportation has the highest expense, followed by inventory, warehousing cost, packing cost, management cost, and finally, ordering cost.

For products with small volume, low weight, and high value, transportation cost simply occupies a very small part of sale. But for big, heavy, and low-valued products, transportation cost becomes important.

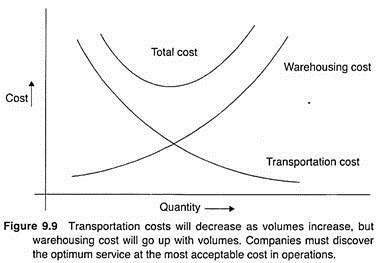

Transportation costs come down as volumes increase. Sending products as truckloads or container-loads spreads the cost to a larger number of units compared to sending in smaller lots. The curve of transportation cost will thus show an inverse relationship when plotted against the quantity of goods.

ii. Warehousing Cost:

The warehousing cost is directly proportional between cost and quantity. As the shipment size increases, companies require larger and more warehouses, and this increases the cost. The cost curve of warehousing cost is an upward sloping curve, showing that warehousing cost increases along with the quantity.

Due to cost pressures, firms try to find out the tradeoff between these two costs. They try to find the ideal shipment size that results in the most efficient cost. This is not always easy, but Figure 9.9 helps understand how cost can be minimized. However, decisions have to be taken depending on the nature of the product and the service standards set by the company.

iii. Total Cost:

When both the expenses are aggregated, we get a total cost curve, which is a U-shaped curve. Generally, the ideal solution would be the point when total costs are minimum. However, this will not always be the case, because of geographical and infra- structural limitations. Further, it would also depend on the kind of service the company wishes to deliver, in which case the company may choose to have more or less warehouses and change the transportation strategy.

Importance of Logistics Management

Responsive logistical service is very important from the point of view of customer as well as competition. It enhances customer satisfaction and creates the opportunity for closer and more profitable buyer-seller relationships. It is often ranked by buyers next to “quality” as a criterion for selecting a vendor.

(1) Place Factor:

Logistics creates place utilities to consumers. Companies lose their customers when they fail to supply goods at the right place. Many products fail in the competitive market when they are not available at the points of purchase at the right time.

(2) Time Factor:

An important utility required by customers is time utility. If products or services are not available at the right time, the customers look for substitutes. If the failure to supply is frequent, customers shift their preferences to the timely available product though it is less satisfying.

(3) Cost Factor:

Experts believe that substantial savings can be obtained in physical distribution area. For this reason it has been described as ‘the lost frontier for cost economies’. Physical distribution decisions when uncoordinated, result in high cost. There is a need to make use of modern operations research tools and computer programming for coordinating inventory levels, transportation modes, and plant, warehouse and store locations.

(4) Promotion Factor:

It is a potent promo-tool in competitive marketing. Companies can attract additional customers by offering better service or lower price through improvements in physical distribution.

Logistics Planning

The logistics planning activity is a continuation of the logistics strategy in the sense that the strategy developed is given a more detailed and practical meaning in the planning phase. Logistics planning, as in the case of the planning process in the other functions, can be considered as arranging the flow of activities.

However, since the activities taken up in the logistics functions are all highly interdependent, there is a need for balancing the system in terms of the individual goals of the components of the logistics system.

For instance, if the warehousing function is given the goal of reducing the inventory and the transportation function is required to reduce the transportation costs, the warehouses would order very small quantities of inventory more frequency, while the transportation department will try to postpone the dispatches as much as possible.

Hence, while each department would try to achieve its costs reduction objective, the system will become totally paralyzed. In order to avoid such problems, the activity levels of the components of the logistical system should be so balanced that all the components should not work at cross purposes in the process of achieving their respective objectives. The importance of detailed planning in logistics is because of this interdependence and the consequent necessity of balancing the goals of the components.

Logistics planning tackles four major problem areas- (i) customer service levels (ii) facility planning (iii) inventory management, and (iv) transportation decisions. Of this, the customer service levels are an outcome of the marketing strategy of the firm and are hence, effectively beyond the purview of the logistical planning process.

The customer service demand is, however, very critical for the logistics planning process since it is instrumental in providing the central objective for the logistical planning function. The entire plan revolves around this aspect. Thus, the logistics planning process is often considered as a triangle of logistical decision-making.

The three major components of the logistical plan in effect attempts to fulfil the objective set under the customer service goals. This is because the level of logistical activity and consequently, the cost of providing the logistical support are totally dependent on the level of customer service envisaged in the strategic plan of the firm.

The level of service provided also affect the design of the logistical system. If a higher level of customer service is planned to be provided, the system would require more facilities such as warehouses, transportation, etc. The inventory to be stocked would also be longer.

Conversely, as the cost of logistics is reduced, the ability of a firm to provide greater service levels is also reduced.

Warehouses in Logistical Systems (Need, Functions and Decisions)

A logistical system would normally require some permanent facilities for storing and supplying the products to the end consumers. Warehouses are locations where the inventory is received, stored, and shipped out according to the demand. Warehouses are usually secure well-protected buildings with special facilities to prevent any damage to the goods that are stored.

Modern warehouses are equipped with sophisticated material-handling equipment that enable easier handling of inventory. Since the primary purpose of a warehouse is to handle inventory, the need for a warehouse would exist whenever a system has some amount of inventory.

While it is difficult to eliminate warehouses or storage locations altogether from the logistical systems, certain types of logistical systems do operate without warehouses. In a direct shipment system, for instance, it is quite possible to eliminate the need for warehousing altogether. According to Simchi-Levi et al. (2000), three generic types of outbound logistics strategies are possible- Direct shipment, Warehousing and Cross-docking.

In direct shipment strategies, goods once, manufactured are directly shipped to the point of sale without being stocked anywhere. While this strategy is practicable and increasingly being adopted by companies such as DELL the world over, it is an extremely difficult strategy to implement, especially when there is need for an extensive distribution network so as to give maximum spatial convenience to the customers.

In the warehousing strategy, however, goods once manufactured are stored in warehouses waiting for orders from the retail outlets or other points of sale. This is the classic strategy where the logistics system consists of a network of warehouses which adjusts the differences in the pattern of production and the pattern of demand.

Given the huge difference in these patterns, both in terms of the size of orders, the timing of the orders, and the time interval permissible between the customer’s order and delivery, warehouses which adjusts these discrepancies are considered to be a must.

In cross-docking, while warehouses do exist, the storage time is reduced to a minimum. In this strategy, items are distributed continuously from suppliers through warehouses to suppliers with the items lying in the warehouses for just a few hours. Such a strategy also requires a high level of coordination between production and sales department.

Cross-docking is a strategy extensively adopted by Wal-Mart, one of the largest supermarket chains in the world. In a typical cross-docking system, goods spend very little time in storage, often less than 12 hours. Being an extremely difficult activity, cross-docking is possible only when certain conditions are satisfied. Lambert et al. (1998) specify certain conditions for cross-docking to be possible.

Some of the important conditions are- (i) the inventory destination is known when stocks are received, (ii) customer is ready to receive inventory immediately, (iii) the number of locations to ship inventories are not high (typically less than 200), (iv) it is possible to pre- label the inventory, and (v) inventory arrives at a state where it is immediately conveyable. The warehousing decisions thus assume great importance if the latter two types of outbound logistics strategies are adopted.

Why Need Warehouses at All?

The main function of a warehouse is to store inventory or perform the critical functions of accumulation, storage, and allocation. Goods from the locations of production are accumulated in the warehouses. This function assumes great importance when the variety of products stored is very high. If the number of items or stock keeping units (SKUs) is large and originates from different plants, the warehouse serves the function of bringing together these supplies from multiple points.

This is needed especially when the orders from the retailers or customers are mostly composite orders comprising an assortment of products. The accumulation function also helps in greater efficiency in the recording of inventory and detection of out-of-stock products for reordering.

In the absence of a warehouse, tracking the inventory position for thousands of SKUs being sourced from several plants becomes a difficult task. Warehouses also serve as points of allocation. It is at the warehouse that the products usually received in bulk quantities are broken down into smaller quantities as per the order received from the retailers or the next entity in the chain.

When the number of retail outlets is high, the allocation function becomes very complex, thus, requiring a highly equipped warehouse where the orders received are picked and packed to be sent to the respective retail outlets. In terms of transportation, warehouses help in achieving greater economies of scale as it becomes possible to transport goods in large quantities.

If the production facility is directly linked to the customers in the absence of a warehouse, the customers’ orders being very small compared to that of the production quantity, full truckload shipments would be difficult to manage every time.

However, when a warehouse exists, orders from several retailers from nearby areas can be clubbed together, sent to the warehouse as full truckload shipment, and from the warehouse the smaller orders can be split and sent to the retailers, thereby reducing the transportation duration of the less-than-truckload shipments.

This is an important consideration for establishing warehouses since the fixed cost being the same, the cost of transporting less-than-truckload quantities through a large distance is an inefficient activity. Warehouses also protect the inventory from damage and pilferage so that in case of slow-moving items, they can be stored safely for a longer period.

Main Functions of Warehousing Operations:

While the main role of a warehouse in an inventory set-up is to store products, the warehouse also participates in the product flow through the channel. Thus, apart from storage, the warehousing function also contributes to bulk-breaking, consolidation, and information activity of the distribution channel.

The warehousing function performs several specific activities as part of integrated logistics system so as to enable the system to function perfectly with the maximum level of efficiency. These activities can be basically classified into three main types- movement, storage, and information transfer.

The movement function itself consists of several activities such as- (i) receiving (ii) transferring (iii) order picking/selection, and (iv) shipping. The receiving activity involves all the activities that are required when product shipments are received from the sender. The main activities at this stage involve the unloading of the goods, updating of the inventory records, inspection of damage, and verification of the merchandise count against the orders and shipping records.

The transfer activity involves transferring the shipment received to locations within the warehouse specifically meant for the storage of that category of inventory to- enable easy access whenever required. The order picking or selection activity takes place whenever the warehouse gets an order from the downstream recipient for the goods stored. Once the order is received, the order is picked and packed to be shipped after selecting the mode of transport, after adjusting the inventory records.

The storage function may be performed on a temporary or a semi-permanent basis. At the initial stage of the logistical system design, the nature of storage in warehouses is decided. Goods can be stored in a warehouse temporarily awaiting an order from the downstream intermediary or else, mainly in the case of seasonal products, goods can be stored for a reasonably long period either to offset the seasonal demand or on the basis of speculation or forward buying.

The information transfer function of warehousing occurs simultaneously with the movement and storage functions. Information on inventory levels, throughout levels (i.e., the amount of product moving through the warehouse), stock keeping locations, inbound and outbound shipments, facility space utilization, order fulfilment data, etc. are the type of information that a firm expects a warehouse to provide. Information technology is increasingly being used to make it easier to capture these kinds of data and transfer it online to decision-makers.

Main Decisions in Warehousing:

The two main decisions with regard to the warehousing function in a firm are- (a) the number of warehouses and (b) the location of the warehouse. A company can also decide about the need to own or the possibility of renting out a warehouse. While this decision has significant financial implication we look at the first two decisions in more detail since the third decision is more related to the company’s decision on vertical integration.

(a) Number of Warehouses:

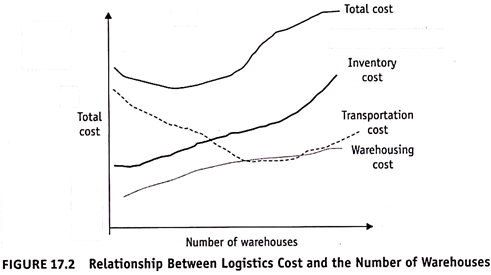

Since the warehouses are locations where inventory is stored, the number of warehouses that a company is planning to set up for carrying out the logistics activity directly affects the inventory level, and hence the profitability of the company.

Four factors are considered in deciding about the number of warehouses:

(i) Cost of lost sales,

(ii) Inventory costs,

(iii) Transportation costs, and

(iv) Warehousing costs.

(i) Cost of Lost Sales:

The cost of lost sales is the stockout cost when a customer’s order is not fulfilled due to lack of availability of stock within the permissible waiting time allowed by the customers. This is basically an opportunity cost, as actual outflow of money does not take place. However, it is an important consideration since in a competitive environment, no firm can afford to lose sales beyond a point due to stockouts.

Also, a stockout would imply wastage of marketing efforts since the customers despite being attracted towards the company cannot be serviced due to logistical problems. It is estimated that when the number of warehouses increases, the possibility of stockout reduces and consequently the cost of lost sales comes down.

This is because every warehouse will have some safety stock provided for the variability in demand and with more warehouses, the selling outlets are closer to the warehouse which makes it possible for the local warehouse to estimate the safety stock for the locality it serves in a more effective manner.

With fewer number of warehouses, each warehouse will be serving a larger number of selling points and consequently the ability to manage the safety stock will be that much more diluted. More warehouses also reduce possibility of stockouts by reducing the lead time between ordering and delivery. However, with greater information dissemination and better transportation facilities now available, it is quite possible to avoid stockouts with fewer number of warehouses.

(ii) Inventory Costs:

The inventory costs are the costs incurred in procuring and holding the inventory for the entire system. Since every warehouse will have a specified safety stock for all the items stocked, the inventory costs are estimated to go up with the number of warehouses. However, the reason why there are such a large number of warehouses is to store large amount of inventory so as to avoid stockouts.

One major problem with a large number of warehouses is the difficulty in identifying and transferring inventory from one warehouse to another. For instance, if the stock for a particular item is about to get over in one warehouse, it may not be easy to detect whether unused st9ck of the same product is available in some other warehouse so that further production is not required. This creates unnecessary accumulation of inventory.

(iii) Transportation-Costs:

Transportation costs of the system includes the costs incurred in transportation for the entire system consisting of the transportation from the production points to the warehouses, as well as the warehouses to the points of sale.

Transportation costs initially decline with the increase in the number of warehouses since it becomes possible to increase the proportion of full truckload shipments in the overall shipments from the production plant. However, when the number of warehouses increases beyond a point, the transportation costs are seen to increase owing to the combination of the inbound and outbound transportation costs.

(iv) Warehousing Costs:

The warehousing costs consist of the cost of renting, leasing, or owning the warehouse as well as the maintenance of the warehouse. Warehousing costs will naturally increase in direct proportion with the number of warehouses.

(b) Warehousing Locations:

Being supply points for the entire market, it is very important that the warehouses are properly located. Proper location will lead to greater customer need fulfilment at a lesser cost. This is because an improperly located network of warehouses will lead to higher lead times and greater transportation costs.

Hence, the objectives of location decisions must be to ensure the required level of customer service with regard to the service output levels with the minimum costs. Over the past several decades numerous studies have tried to develop an effective and robust methodology for solving location problems. Several approaches have been considered. While analysts have been able to find out highly satisfying solutions to specific problems, a universally acceptable solution is still elusive.

The location or site selection decision can be approached from macro and micro perspectives. According to Lambert et al. (1998), the macro perspective examines the issue of locating a warehouse within a broad geographical area and concerns issues such as whether the warehouse should be located near the plant or the market. The micro perspective takes a more precise approach and attempts to pinpoint locations using optimization techniques.

Macro Perspectives on Warehouse Locations:

Most of the macro approaches on warehouse location try to give a more general solution to the problem. The main issue seems to be whether the warehouse should be near the production plant, the market, or midway between both. Various approaches and concepts are used to justify the solutions proposed.

Most of those who proposed these models are called economic geographers. Karl Emil Maximilian Weber, the German economist, looks at this issue from the point of view of the weight addition after the manufacturing process is complete. He classifies products into those whose combined weight reduces after raw materials are converted into finished products, such as steel, or products where there is an increase in the weight after production.

The easiest example for the second category is the soft drinks industry which uses water as a ‘ubiquitous’ commodity for increasing the bulk of the product. Weber feels that for those products whose weight reduces after the production process is complete, the warehouses should be located near the factory rather than the market.

In the case of the second category of products, the warehouses should be located near to the market. The logic behind these solutions is the apparent reduction in the transportation cost if the warehouses are located in such a manner.

Micro Perspectives on Warehouse Locations:

Most of the micro perspectives on warehouse locations tend to give specific solutions to problems concerning facilities locations. One of the most popular approaches is the centre of gravity method. The approach considers the transportation rates and the point volumes for arriving at the exact location for the warehouse.

Centre of Gravity Method:

The centre of gravity method tries to minimize the cost of logistics by selecting an appropriate site for locating the warehouse when the transportation cost as well as the volume to be shipped to various markets is known. It is a very simple model which uses straightforward minimization principles.

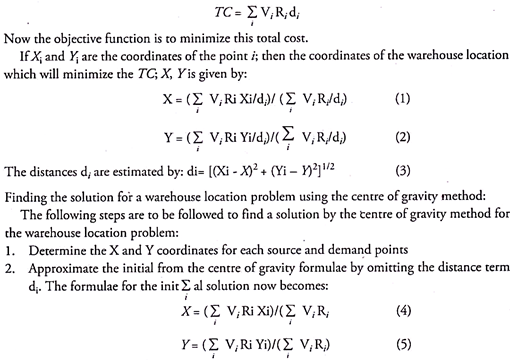

However, when we try to bring in more information, the computations can be quite complex and would require powerful computer programs. Here we will look at a simple example for illustration. Assume that Vi is the volume to be transported to a retailer, Ri is the transportation rate per ton per km for the product to be transported, and di is the distance from our suggested warehouse location.

Now if there are such locations; the total cost of sending goods from the suggested warehouse to these locations is given by:

3. Using X and Y from step 2 calculate di according to equation(3).

4. Substitute this value of di into equations (1) and (2) to get revised values for the coordinates of X and Y.

5. Recalculate value of di by substituting the value of X and Y again in equation (3).

6. Repeat steps 4 and 5 until either of the X and Y coordinates do not change for successive iterations or the change is so small that there is no need to continue the calculations.

7. Calculate the total cost for the best location using the equation for total cost.

While the centre of gravity method is quite simple and easy to understand, it makes certain assumptions that may not always be the case in practice.

(a) For instance, in this method the location decision is made after considering only the variable cost as the fixed cost of setting up the warehouse could vary from one location to another based on the terrain, access to roads, etc. and that is why it is not considered.

(b) The method tries to come out with the most optimized location by considering the straight- line distances between points. This may not work out perfectly every time. The presence of a river or some other geographical obstruction, such as mountains, could make the use of radial distances as approximations of actual distances impractical.

(c) The market is considered as a single point while in reality it is not so. It is always much dispersed. While this disparity can be explained in terms of using the centre of gravity of the mark as the point to be considered, it might not always work out properly.

(d) The transportation cost is assumed to increase in proportion to the distance, but in reality the transportation cost will normally have a fixed component and a variable component.

The example consists of the decision regarding a single location. In reality, however, it is important to set up multiple facilities to serve the market. The multi-facility location problem is much more complex and involves more variables. The usual approach is to develop a first- cut solution either by making simple assumptions or using heuristics, and then fine-tuning the solution with more advanced methodologies.

In this type of approach, the production points and the market points are arbitrarily assigned to certain locations so that clusters are formed with regard to each of the proposed warehouse location. These clusters consist of the market points and production points assigned to each of the warehouses.

At this stage, the centre of gravity is calculated for each of the clusters, and then based on the initial solution, points are reassigned to each of the location points. This process is continued till the total cost is minimized.

Cost-Volume-Profit Analysis:

This is another method used for warehouse location decision. It is a simple method which uses the break-even analysis to select from a set of locations. In this method we decide about a few alternative locations and then select from this set of alternative locations. We also estimate the fixed and variable costs for each of the locations.

The procedure for locational cost—volume analysis involves the following steps:

1. Determine the fixed and variable costs for each location alternative. The variable cost is the cost incurred per ton per km for transporting from that location to all the markets and also receiving products from all the production plants.

2. Plot the total cost lines for all location alternatives on the same graph.

3. Determine which location has the lowest total cost for the expected level of output.

This method assumes the following:

1. Fixed costs are constant for the range of probable output.

2. Variable costs are linear (i.e., variable costs per unit are constant) for the range of probable output.

3. The required level of output can be closely estimated.

4. Only one product is involved.

Both the methods use several assumptions that may not always reflect reality. Also, when multi-location decisions have to be taken, both the methods are found to have severe limitations. However, to arrive at basic solutions which can be later refined, these methods are useful.

To arrive at warehouse decisions that require locating several warehouses with different products, advanced mathematical techniques such as mixed integer linear programming or simulation models are used. Computer packages, such as LOGWARE, are available for finding the solutions to these problems.

Decisions Involved in the Management of Logistics

Management of logistics requires decisions concerning the following:

1. Network Design:

First of all, it is necessary to decide the number and location of facilities needed for logistics operations. Proper design of network and infrastructure improves efficiency of logistics. The facilities in this network are manufacturing plants, materials handling system, distribution system, order processing system, after sale service, etc.

2. Information System:

In logistics, information is needed to forecast sales and to process customer orders. Sales forecasting helps in inventory management. Correct information is necessary to avoid errors and delays in order processing.

3. Transportation:

A cost effective and speedy transportation system improves efficiency of logistics. Roadways, railways, airways and waterways are the different modes of transport. Road transport is suitable for carrying goods of medium bulk and weight over short distances and for point to point service. Rail transport is suitable for carrying heavy goods over long distance. Air transport is suitable for carrying light and valuable goods at a fast speed. Water transport is appropriate for carrying bulky goods of low value.

4. Warehousing:

Proper storage of goods is necessary to serve customers efficiently.

Warehousing decisions are as follows:

(a) How many warehouses

(b) What type of warehouses

(c) Where to locate warehouses

(d) What size of warehouses.

5. Procurement:

Acquiring raw materials, semifinished items and finished products is an important part of logistics. It consists of several activities, e.g. requirement planning, sourcing suppliers, negotiation, order placement, receipt and inspection, quality assurance, handling, etc. It provides support to manufacturing and resale operations.

6. Packaging and Labelling:

‘Packaging’ involves designing and producing appropriate packages for various products. Effective packaging protects the product, makes product handling convenient, and serves as a silent salesman, ‘labelling’ refers to putting identification marks on packages. A label provides information about the brand, grade, price, manufacturing date, expiry date, etc. It may be a part of the package or may be attached to the product.

7. Inventory Management:

A business firm maintains inventory to fulfil orders of customers. The amount of inventory will depend upon anticipated demand and time involved in replenishment of inventory. Inventory control involves maintaining inventory at the optimum level so that the costs of carrying inventory and ordering costs are minimised without loss of sales. The nature and quantity of various items to be kept in stock are decided so as to minimise investment in inventory and at the same time avoid interruptions in production process and selling.

8. Order Processing:

The steps involved in executing customer orders is known as order cycle. It begins when customers place an order and ends with despatch of product to the customer. The order processing system affects customer service significantly. When there are errors and delays in processing of orders, the firm loses customers to its rivals. Therefore, logistics manager must design and operate a quick accurate and efficient order processing system to retain customers and ensure repeat orders.

Materials Management, Warehousing and Distribution

Once purchasing managers procure raw and packaging materials or component parts, logistics personnel must manage them in a cost-efficient manner that supports manufacturing operations. Materials management involves the inbound movement and storage of materials in preparation for those materials to enter and flow through the manufacturing process.

Effective materials management benefits the company in the following four ways:

1. Reduces procurement, transportation, and production costs through economies of scale.

2. Coordinates supply and demand for materials. Warehouses can be used to store the various types of inventory—cyclical, safety, and anticipative stocks—until needed.

3. Supports manufacturing activities. Materials management ensures that stored or recently received materials get to the production floor when they are needed.

4. Supports marketing objectives by making sure that goods are available to ship to customers in an efficient and effective manner.

Materials management typically occurs in a warehouse. To maximize the benefits of materials management, logistics personnel must effectively coordinate various warehouse functions.

Warehouse Functions:

Warehouses perform a number of different types of activities.

These activities can be organized into three basic functions:

1. Storage,

2. Movement, and

3. Production.

1. Storage:

Storage involves holding inventories until they are needed. Storage may be temporary or semi-permanent. Temporary storage implies that the goods are warehoused for a short period of time. Temporary storage can also be used to accumulate goods from small shipments for consolidation into larger shipments to reduce transportation costs.

Semi-permanent storage is used to warehouse inventory needed to meet demand over and above normal replenishment, such as – seasonal stock, or to house extra inventory purchased as part of a push strategy or through volume discounts.

2. Movement:

The movement functions of a warehouse include receiving, put-away, picking, shipping, and delivery to a production area. Receiving involves unloading goods from a carrier, updating inventory records, and quality inspection, if required. Put-away refers to moving goods to their temporary or semi-permanent storage location and updating inventory records.

Picking involves retrieving materials from storage and bringing them to manufacturing to fulfill a production order, or retrieving finished goods from storage and preparing them for shipment to fulfill a customer order.

Shipping involves loading picked items onto transportation vehicles, updating inventory records, and preparing the necessary documents to transport the items.

3. Production:

Some warehouses also perform a production function. This may include such activities as light assembly of products like store displays, customizing products for customers (e.g., mixing different products into a shipment for customers that do not need large quantities of any one product), and refurbishing returned goods.

Distribution Centers:

Distribution occurs when a company ships its goods to its customers. This activity is performed by distribution centers. A distribution center (DC) is a type of warehouse used specifically to store and ship finished goods to customers. Distribution centers perform all of the same storage and movement functions as warehouses, as well as additional activities to support company and marketing objectives.

The four additional functions DCs perform include:

1. Product accumulation,

2. Product sortation,

3. Product allocation, and

4. Product assortment.

1. Product Accumulation:

Product accumulation involves receiving goods from various suppliers, storing the goods until they’re ordered by a customer or other company- owned facility, and consolidating orders to achieve transportation economies of scale. Orders from customers are collected until enough goods are ordered to fill vehicles, which reduces transportation costs.

2. Product Sortation:

Product sortation refers to gathering goods with similar characteristics in one area of the DC to facilitate proper inventory controls and effectively provide customer service. For example, a company that sells sunscreen, which is regulated by the United States Food and Drug Administration (FDA), must keep expired products off store shelves.

Product sortation enables such companies to maintain control over their inventory and avoid accidently shipping goods that are no longer fit for sale.

3. Product Allocation:

The product allocation process involves picking available goods to fill customer orders. Distribution centers can be set up to pick full pallets of goods, full cases of goods, or individual goods. The ability of a DC to allocate goods down to a single piece allows customers to buy in quantities that make sense for their business.

Walgreens, for example, would not want to order a full pallet of ruby red lipstick that would take years to sell. The DC’s allocation function enables Walgreens to order only the quantities it needs.

4. Product Assortment:

A distribution center’s product assortment function also supports ordering smaller, more economic quantities of goods. Product assortment occurs when the DC mixes goods coming from multiple suppliers into outgoing orders so that each order includes a variety of goods rather than just one type of good. Customers often require small quantities of goods from a variety of suppliers.

The product assortment function of a distribution center allows companies to meet this need in a cost-effective way by combining orders for a variety of products going to the same location in the same truck to save money.

Distribution Network Design:

The number and location of DCs are among the strategies a company can use to support its marketing objectives. Should the firm establish a few, large centralized DCs, or more DCs that are closer to the customer but hold less inventory? The answer has to be based on the company’s marketing and supply chain strategies.

Some of the factors a company needs to consider when designing its distribution network include:

1. Inventory levels – The more facilities in the network, the higher the overall inventory in the system. The additional inventory can benefit the company if demand unexpectedly increases, but it adds to inventory carrying costs.

2. Operating expenses – The fewer facilities in the network, the less operating expense incurred. With fewer facilities, the company will require fewer management and clerical employees and less information technology equipment to conduct distribution activities.

3. Customer service – More facilities result in faster delivery to customers since facilities will be closer to markets. However, centralized facilities generally result in better product availability, leading to superior customer service with less inventory investment.

4. Transportation costs – More facilities lead to higher transportation costs from production sites and suppliers to the warehouses or DCs. However, transportation costs between the facilities and customers may be lower due to their close proximity.

In addition to these factors, distribution network decisions will be heavily influenced by the structure of a company’s distribution channels. How a company uses these intermediaries, where they are located, their inventory and customer service expectations, and the extent of business the company does with them will influence distribution network decisions.

For example, a company that counts Walmart or another very large company as a customer will likely want to place its own DCs close to those owned by the large company to service them faster.

Retailers:

Retailers like Walmart represent an important distribution channel. A retailer is a firm that sells mainly to end-user consumers. Retailers can take the form of large chain stores directed by corporate offices that centralize purchasing, advertising, human resources, and other functions. Walmart, as well as Target and Dillard’s, are examples of chain stores.

Independent retailers, such as – a local book store or gift shop, may have only one or a few stores. Retailers can also be franchised from a large corporation. In such a case, the corporation sells the franchise store to an individual or individuals to operate, while maintaining control over management training, advertising, the supply of products being sold, and many other aspects of the store. Sonic and Radio Shack are examples of franchises.

Not all retailers operate brick-and-mortar stores. Some companies perform direct retailing, selling to customers at their homes, at their offices, or through parties at a customer’s home at which the customer’s friends and family watch product demonstrations by a company representative.

Mary Kay Cosmetics is an example of a direct retailer. Telemarketing and mail order retailing are other nonstore forms of retailing. Mail order retailing relies on purchases made from catalogs mailed to customers’ homes. Bass Pro Shops is an example of a company that has practiced catalogue sales successfully for many years.

Online retailing (sometimes called e-tailing), or purchasing through a computer, tablet, or smartphone, is the fastest growing retailer category. Online retailers such as – Amazon have taken advantage of the spread of electronic devices and the Internet throughout the world to sell goods anywhere there is an Internet connection.

Because of the convenience consumers expect from online retailers, the decisions they make with regard to their distribution network design are especially critical to their ultimate success.

Strategic Issues in Logistics Management

Marketing managers face a particular challenge today – how to promote those products whose features are perceived as being more-or-less homogenous by customers? Since any change in product, promotion, or price has only a temporary impact in their markets, how can a sustainable competitive advantage to be gained? Bowersox, Mentzer, and Speh (1995) point out that competitive advantage may not lie in changes in the product, promotion, or pricing strategies of the company, but in improving ancillary services, such as logistics.

Day and Wensley (1988) say that improving logistics services is most likely to yield a sustainable positional advantage in the market when implemented through changes in the corporate infrastructure – people, technology, facilities, and/or strategic corporate relationships.

Objective of Strategy – Customer Satisfaction:

Porter (1985) defines competitive advantage as sustaining superiority of interrelated activities within the firm.

Treacy and Wiersema (1993) ask questions about three companies:

1. How did Dell come out of nowhere and get ahead in the personal computing business?

2. How did Home Depot gain market shares when there were retailers selling similar goods?

3. How did a startup company, Nike, beat an established player, Adidas?

The three questions have the same answer – these companies were able to define and increase what customers valued, but more importantly, were able to deliver it. They could do so by achieving ‘operational value’, that is, providing consumers with products they liked, at competitive prices and delivered with minimal difficulty or inconvenience.

The steps identified to achieve this were as follows:

First, they defined value for the customer in their respective area.

Second, they built powerful and cohesive systems that delivered value to the customer.

Third, they raised customer expectations that were beyond the reach of the competition.

In other words, while the products may be copied, the processes are difficult to replicate. This is the source of competitive advantage. Several researchers have used different nomenclature to describe this, but they all point to skills and processes as means of achieving lasting customer value.

Different studies point to the fact that logistics is central to providing competitive advantage. Achieving logistics superiority is difficult simply because it involves a unique combination of people, technology, facilities, strategic relationships, and infrastructures of the company. While one or few of these can be copied, this unique combination is impossible to replicate for any competitor.

The idea is also mentioned by Day and Wensley (1988), who have used the term ‘positional superiority’ to mean a relative superiority in the skills and resources a business deploys, while Stalk, Evans, and Shulman (1992) refer to ‘capabilities-based competition’ as the ability to sustain competitive positioning. It is up to companies how they achieve this.

Woods (1991) mentions logistics as the strategic ‘battleground’ which displaces manufacturing, marketing, and quality as source of differentiation and hence the focus of top management attention. Bowersox, Mentzer, and Speh (1995) term ‘logistics leverage’ as a key marketing strategy that can potentially create and maintain long-term positional advantage. They define logistics leverage as the achievement of excellent and superior infrastructure-based logistics performance which, when implemented, creates recognizable value for customers.

Through logistics leverage a company can achieve ‘positional advantage’ in the mind of the customer—unique, distinct, and difficult to replicate by competitors. Anderson and Narus (1995) say that many firms now stress upon logistics capabilities as a means of creating differentiation.

Channels help the company to make the product available. The success of channel efficiency and effectiveness is dependent on logistics operations to fulfill demand. It is the ‘last mile’ of the strategy, because if goods are not available at the point of sale, sales cannot be accomplished.

Hence, the logistics network must be integrated with the distribution channels of the firm. The distribution channel is as an interface between the customer and the company. The effectiveness of this interface is greatly dependent on logistics operations.

Competitive advantage is, thus, achieved through many discrete activities that a company does, such as designing, producing, marketing, delivering, and supporting its product. Value chain activities can be categorized under two types – primary activities and support activities. Primary activities consist of inbound logistics, operations, outbound logistics, marketing, sales, service, infrastructure, and delivery.

Support activities consist of human resource management, development, and procurement. To gain competitive advantage, a company must achieve customer value by creating greater differentiation in its primary activities.

Differentiation can be achieved by logistics management. It can achieve both – a cost and productivity advantage, as well as a value advantage. The former can be achieved through better capacity utilization, inventory reduction, and closer integration with suppliers. Gaining advantage through superior customer service is also a logistical advantage that companies can achieve.

Some of the key issues in gaining logistical advantage are given as follows:

Key Issues in Competitive Strategy:

The objective of competitive strategy in logistics is customer service and satisfaction. Components of service standards include the length of time that a customer has to wait before being served, percentage of orders fulfilled, percentage of incidents when there was a stock-out, and finally, whether the customer was satisfied enough to return. These are summed up in the 4Rs of customer service.

i. Responsiveness:

Responsiveness refers to the speed in responding to customer demands. This must be reflected in all phases of transaction, from pre-sales enquiry to fulfilling the customer order. Information and communication technologies improve the degree of responsiveness; how these are used effectively depends on companies.

ii. Reliability:

Reliability is the degree of trust the customer has in a company’s capability to deliver. Companies achieve this through inventory planning and better logistics. Companies must try to achieve consistency in time-delivery-performance parameters. The prime objective of a successful logistics system is thus to be seen as reliable by the customer.

iii. Rationalization: