After reading this essay you will learn about:- 1. Concept of Industrial Engineering 2. History and Development of Industrial Engineering 3. Applications.

Essay # Concept of Industrial Engineering:

The American Institute of Industrial Engineers (AIIE) has defined the special field of industrial engineering as “Concerned with the design, improvement and installation of integrated systems of people, materials, equipment and energy. It draws upon specialized knowledge and skill in the mathematical, physical and social sciences together with the principles and methods of engineering analysis and design to specify, predict and evaluate the results to be obtained from such systems”.

Industrial Engineering is engineering approach to the detailed analysis of the use and cost of the resources of an organisation. The main resources are men, money, materials, equipment and machinery. The Industrial Engineer carries out such analysis in order to achieve the objectives (to increase productivity, or profits, etc.) and policies of the organisation.

An Industrial Engineer’s techniques go beyond the mechanical cost factor. He is associated with organization structure, administrative techniques, human (labour) problems and at the same time he understands the relationship between efficiency and consent (of the working group). Essentially, the industrial engineer is engaged in the design of a system and his function is primarily that of management. If industrial engineer had to focus on only one concept to describe his field of interest and objective, it would have to be productivity improvement.

ADVERTISEMENTS:

Productivity improvement implies:

(i) A more efficient use of resources,

(ii) Less waste per unit of input supplied, and

(iii) Higher levels of output for fixed levels of input supplied and so on.

ADVERTISEMENTS:

The inputs may be:

(i) Human efforts,

(ii) Energy in any of its myriad forms,

(iii) Materials, and

ADVERTISEMENTS:

(iv) Invested capital etc.

Succinctly stated, the mission would be to try to produce more or to serve better without increasing the resources being consumed.

Essay # History and Development of Industrial Engineering:

What industrial engineering is today and aspires to be in future is determined by what has gone before. Industrial engineering had its roots in the Industrial Revolution (around 1750); it was nourished by individuals who sought to advance organisation and management principles at an early date; it emerged as a separate discipline and was formulized in the late nineteenth and early twentieth century’s; and it achieved maturity after World War II.

The Industrial Revolution resulted from the advent of new inventions, especially in the textile industry, then steam engine, advances in metal cutting and the production of machine tools. These led to factories with large number of workers. With the growth in the size of industries, came the beginning of management and management thinking.

ADVERTISEMENTS:

The application of the scientific method of analysis, experimentation and practical demonstration had been extended to the production of machine tools, more complicated processes, and better products. Now it was being extended to man’s thinking on organisation and management principles and methods. Scientific Management as a professional approach was yet to come, waiting on the works of pioneers in the field.

Historians of science and technology might argue as to the beginning of industrial engineering. The generally accepted beginnings relate to the work done by F.W. Taylor, who was concerned primarily with concepts of productivity, even though he did not refer to it in those terms. Prior to Taylor’s work, however, there were others, whose writings referred to concepts that ultimately became associated with industrial engineering, whose impact on Taylor is difficult to assess.

One of the earliest of these is Adam Smith’s treatise The Wealth of Nations, published in 1776. The concepts Adam Smith expressed concerning the proper division of labor, while not original, nevertheless became an important factor in the unfolding of the impending Industrial Revolution. The writings of Adam Smith and those of both his students and contemporaries were important milestones in the development of the factory system and of the Industrial Revolution which it created.

Adam Smith was an economist not an engineer, and as a result, his writings came from this perspective. A more direct line to the pioneering in industrial engineering might be provided by Charles W. Babbage who wrote On the Economy of Machinery and Manufactures in 1832. Perhaps one of the most important contributions to industrial engineering that Babbage made, although it was not so recognized at the time, was his attempt to build a computer–or as he referred to it, an Analytical Calculating Machine.

ADVERTISEMENTS:

During the latter half of the nineteenth century, there were others, primarily in United States, who clearly provided the impetus and thinking that led to interest in the start of formal education in the field of Industrial Engineering. One such person was Henry R. Towne. Towne emphasized the economic aspects and responsibilities of the engineer’s job in a paper that he presented to the ASME.

Another active worker and writer was Frederick A. Halsey, the father of the Halsey premium plan of wage payment. A third individual who laid much of the ground work for the developing activity-industrial engineering was Henry L. Gantt, the originator of the Gantt Chart. Probably the most often quoted and generally acknowledged instigator of studies that have led to the discipline of Industrial Engineering and who was himself a mechanical engineer, was Frederick W. Taylor.

Though Taylor did not use the term industrial engineering in his work, his writings and talks under the aegis of ASME are generally credited as being the beginning of the discipline — industrial engineering. Taylor, however, preferred the term Scientific Management. What Taylor was proposing, was a more rational and planned approach to the problems of product ion and shop management. Besides management problems, Taylor was active in research on metal cutting and the technical problems of production as well.

The other giant of the early dates was Frank Bunker Gilbreth. He, too, was an engineer and obviously had been impressed by the work and writings of Taylor. Taylor focused on planning and organization of work whereas Gilbreth (husband and wife) was interested in improving the efficiency through improvement of methods of doing a work i.e., method study.

ADVERTISEMENTS:

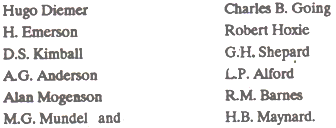

There were many others who should be recorded in any detailed history of the field of industrial engineering, however, space limitations do not permit more than a mention of their names:

As the result of the developments in the field of industrial engineering, in 1908, the first separate departments of Industrial Engineering were established at Pennsylvania State University and at Syracuse University. The first Ph.D. granted in the U.S.A in the field of industrial engineering was the result of research done in the area of motion study. It was awarded to Ralph M. Barnes by Cornell University as recently as 1933.

Most of the leaders of the early work in industrial engineering focused their activities on motion study and related areas of work at the individual work place to make it more productive. The 1930s were a decade of economic hardship and social unrest. The great depression made management extremely cost conscious and created an environment in which industrial engineering principles and techniques were given serious consideration and fairly widespread application.

ADVERTISEMENTS:

At the close of the decade, the impact of World War II was beginning to be felt in terms of increased industrial production; this provided a further stimulus to industrial engineering precepts and practices. Trade unionism grew extensively in the 1930’s and workers felt less fear of wage rate cutting. Many modern industrial engineering techniques had their genesis during the period 1940-1946. Predetermined time standards (such as MTM and Work-Factor), value engineering and systems analysis are a few of these.

One of the fascinating products of World War II was the activity which came to be known as Operations Research (O.R.), basically, which is a process of applying statistical and higher mathematical techniques to the solution of real-world problems. A highly significant era in the development of industrial engineering began after World War II. A great many new activities developed and the application of principles and techniques was vastly broadened.

The activities were:

(i) Industrial engineering and computer;

(ii) Development of system analysis and design;

(iii) Application of mathematical and statistical tools;

ADVERTISEMENTS:

(iv) Network planning techniques and their application;

(v) Value engineering; and

(vi) Behavioural science and human factors.

It was primarily these two developments-the mathematical advances and their applications in the field of operations research and the development of high speed, stored programme digital computer-that literally changed industrial engineering from a non-quantitative empirical science to one of considerable mathematical sophistication and caused it to be considered a hard science.

An additional element should be considered in reviewing the development of industrial engineering and that is-human factors or human engineering or ergonomics. As a result of these developments, the industrial engineer of today has many more sophisticated tools with which to analyse his problems and to design new and improved systems.

Essay # Applications of Industrial Engineering:

Before 1940, Industrial Engineering was mainly applied to manufacturing industries for improving methods of production, to develop work standards or to formulate production control and wage policies.

ADVERTISEMENTS:

Later on, the use of industrial engineering also speeded to non-manufacturing activities such as construction and transportation, farm and air-line operations and maintenance, public utilities, government and military operations.

Still today, Industrial Engineering finds major applications in manufacturing plants and industries.

In an industry besides the production, other departments utilising industrial engineering concept are Marketing, Finance, Purchasing, Industrial Relations etc.