After reading this article you will learn about the economics of power generation.

Power generation economics is important in controlling total power costs to the consumer. A study of power plant economics assists in power plant selection, and in introducing cost reduction techniques in plant operation.

The power plant designer must consider the most economical conditions and not the most efficient conditions, as profit is the most important criteria in the design of the plant and its effectiveness is measured in financial terms. The main objective of the plant is to bring out the cost of energy produced to minimum. The efficiency of the plant is only one factor among many others that determines the energy cost.

The cost of power to a consumer includes the following three types of costs:

ADVERTISEMENTS:

1. The cost of generation (Fixed + operation costs),

2. Cost of transmission and distribution,

3. Miscellaneous costs like overheads including taxes etc.

There are large numbers of ways for producing power. The main function of designer is to study the economical aspects of different available alternatives. Here, we shall discuss different elements of costs, which are required to be considered for determining the most economical alternative.

ADVERTISEMENTS:

Economy is the main principle of design of a power plant. Power plant economics is important in controlling the total power costs to the consumer. Power should be supplied to the consumer at the lowest possible cost per kWh. The total cost of power generation is made up of fixed cost and operating cost. Fixed cost consists of interest on capital, taxes, insurance and management cost. Operating cost consists of cost of fuel, labour, repair, stores and supervision.

The cost of power generation can be reduced by:

(i) Selecting equipment of longer life and proper capacities.

(ii) Running the power station at high load factor.

ADVERTISEMENTS:

(iii) Increasing the efficiency of the power plant.

(iv) Carrying out proper maintenance of power plant equipment to avoid plant breakdowns.

(v) Keeping proper supervision as a good supervision is reflected in lesser breakdowns and extended plant life.

(vi) Using a plant of simple design that does not need highly skilled personnel.

ADVERTISEMENTS:

Power plant selection depends upon the fixed cost and operating cost. The fuel costs are relatively low and fixed cost and operating and maintenance charges are quite high in a case of a nuclear power plant. The fuel cost is quite high in a diesel power plant and for hydro power plant the fixed charges are high of the order of 70 to 80% of the cost of generation. Fuel is the heaviest items of operating cost in a steam power station.

A typical proportion of generating cost for a steam power station is as follows:

Fuel cost = 30 to 40%

Fixed charges for the plant = 50 to 60%

ADVERTISEMENTS:

Operation and maintenance cost = 5 to 10%

The power generating units should be run at about full load or the load at which they can give maximum efficiency. The way of deciding the size and number of generating units in the power station is to choose the number of sets to fit the load curve as closely as possible. It is necessary for a power station to maintain reliability and continuity of power supply at all times.

In an electric power plant the capital cost of the generating equipment’s increases with an increase in efficiency. The benefit of such increase in the capital investment will be realised in lower fuel costs as the consumption of fuel decreases with an increase in cycle efficiency.

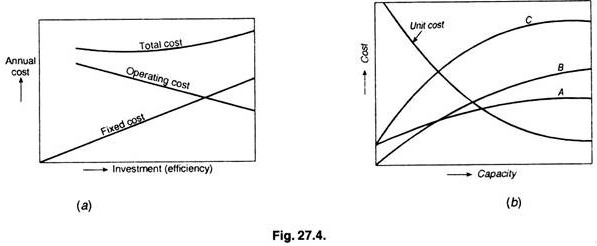

Figure 27.4 (a) shows the variation of fixed cost and operation cost with investment.

Figure 27.4 (b) shows the variation of various costs of power plant versus its capacity.

Curve A shows variation of engineering and labour cost whereas curve B indicates material cost the curve C indicates total cost.

Unit Cost = Total cost/Capacity