Introduction:

Location of an industry is an important management decision. It is a two-step decision: first, choice of general area or region and second, the choice of site within the area selected. Location decision is based on the organisations long-term strategies such as technological, marketing, resource availability and financial strategies.

The objective of plant location decision-making is to minimise the sum of all costs affected by location.

Plant location is important because of the following:

(i) Location influences plant layout facilities needed.

ADVERTISEMENTS:

(ii) Location influences capital investment and operating costs.

Location decisions are strategic, long-term and non-repetitive in nature. Without sound and careful location planning in the beginning itself, the new facilities may create continuous operating problems in future. Location decision also affects the efficiency, effectiveness, productivity and profitability.

The location decision should be taken very carefully, as any mistake may cause poor location, which could be a constant source of higher cost, higher investment, difficult marketing and transportation, dissatisfied and frustrated employees and consumers, frequent interruptions of production, abnormal wastages, delays and substandard quality etc.

Therefore, it should be based upon a careful consideration of all factors that are essentially needed in efficient running of a particular industry. The necessary factors in the selection of plant location vary among industries and with changing technical and economical conditions.

ADVERTISEMENTS:

Site selection is not an easy problem because if the selection is not proper then all money spent on factory building, machinery and their installation etc., will go as waste and the owner has to suffer a great loss. Therefore, while selecting a site, owner must consider technical, commercial, financial aspects which may provide maximum advantages.

It is sometimes possible that all the requirements and features of ideal site may not be available at one particular location but then it will be advantageous to find out suitable site with combinations of all essential requirements of the particular industry to be established as explained in following paras.

Locational Economics:

The selection of the location for an industrial plant is a long time commitment. A new enterprise may be suffered throughout its life due to unfavourable location. Once a plant has been built, the expense and disruption of activities necessary to move it to a more favourable location is quite impracticable. Therefore, the search for plant site justifies very careful consideration.

For evaluation of economical location following factors should be considered:

ADVERTISEMENTS:

1. Raw material procurement.

2. Proximity of market.

3. Availability of labour, their training and compensation.

4. Availability of power.

ADVERTISEMENTS:

5. Availability of finance.

6. Miscellaneous considerations like donations, subsidies, taxes and non-interference by government or local bodies, war and political effects and other facilities or bottle necks.

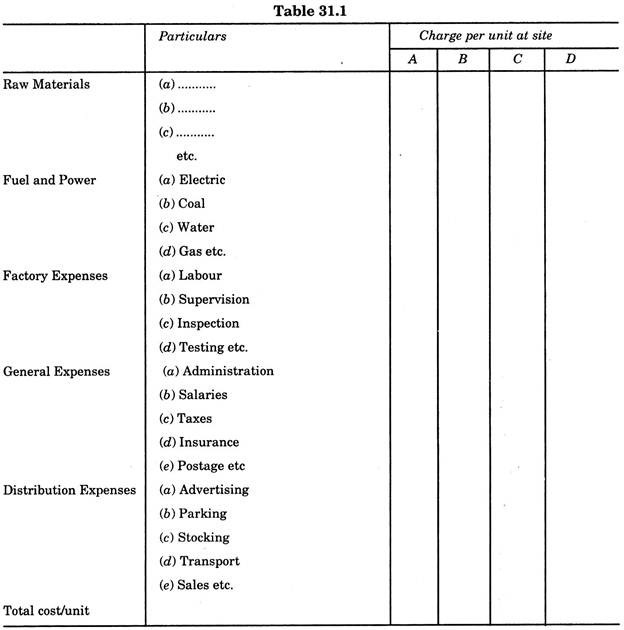

For comparing, the problem is divided into five main factors. The cost of each factor or sub- factor is calculated per unit as shown in Table 31.1, which will help us in deciding most economical site.

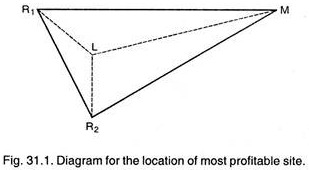

Let R1 and R2 be the two available sources of raw material supply, one place of market or consumption is M, and L is the location of the factory. Then, if L is at M, only freight on raw material will be paid or if L is at R1 or R2, there will be only distribution charges on the manufactured goods.

ADVERTISEMENTS:

Now, again if an intermediate place is selected both incoming and outgoing freights will be paid. Actually in practice, a comparison should be made of each element of the cost required to be involved, if the plant is erected at each of these alternative locations as shown in triangular form in Fig. 31.1.

In order to explain the mechanics of optimal choice of location the following examples are taken. It is not necessary to consider all the factors of site selection given in Table 31.1, only the most effective factors can be considered. An optimal location is one, which is the best in given and existing circumstance.

Example 1:

ADVERTISEMENTS:

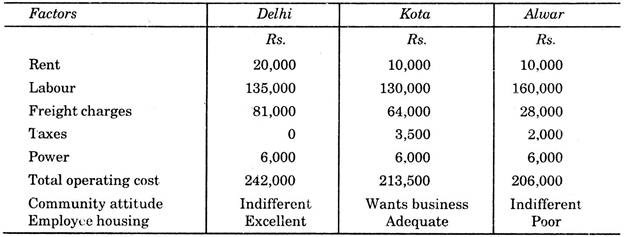

A comparison for three cities is given below on the basis of effective factors which effect the locational economic:

Now on the basis of operating costs alone Alwar city would appear to be best location. If we include the other factors such as community attitude and employee housing, Kota offers the best possibilities for location and would probably be chosen.

ADVERTISEMENTS:

Example 2:

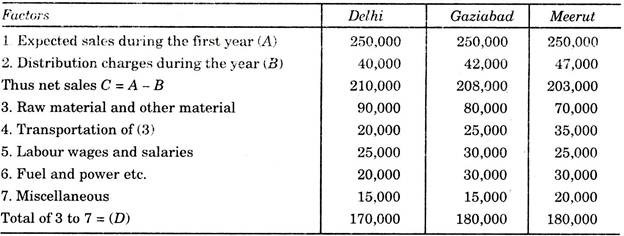

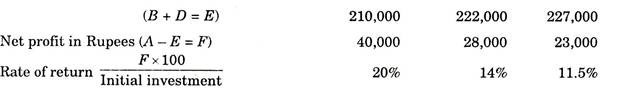

A new industrialist wants to locate a small factory. On surveying he found the three possibilities of Delhi, Gaziabad and Meerut with different advantages. The initial investment is going to be of the order of Rs. 2 lacs. The industrialist wants to calculate the rate of returns of the three proposed sites with highest rate of returns will be the optimal choice of location for the factory.

Out of above factors 1 and 2 can be headed under sales and distribution cost and other five factors under production cost.

Now Total cost of production and distribution, i.e.,

Thus location of the factory at Delhi with 20% rate of return is the optimal choice for the factory, as it gives maximum rate of return. The rate of return for Gaziabad and Meerut are 14% and 11.5% respectively. However from analysis for the cost of raw material and other materials, Delhi is costlier with Rs. 90,000 in comparison with Rs. 80,000 and Rs. 70,000 respectively at Gaziabad and Meerut.

ADVERTISEMENTS:

The rate of return is highest at Delhi due to the following reasons:

1. Lower distribution costs.

2. Lower Transportation costs for raw materials and others.

3. Lower fuel and power supply cost.

Although an analysis such as given in above example does not make the final location decision. Management may find it quite useful in knowing the facts on which a sound economic choice is based.

Market Location:

ADVERTISEMENTS:

To solve such problems a market analysis of the area is conducted and answers of the following questions can be found out:

1. If there is a market which could be served and if retail price of product can be reduced?

2. Whether quick delivery of the product can be made by better plant location to the particular market?

3. Whether there is a competitor for the product in the market? Whether demand for product may increase? Whether an additional plant is required to meet the future demand?

4. What is the potential purchasing power of the market?

5. What are the buying habits of local people, and what must be done to fit your service to these habits?

Economical Aspects:

ADVERTISEMENTS:

Locational economics for an enterprise includes a consideration of the product to be manufactured, the processes and machinery to be used, and the service and facilities required.

To know this the following factors may be studied:

1. Product:

(a) Nature,

(b) Volume, and

(c) Value.

ADVERTISEMENTS:

2. Production process:

(a) Continuous,

(b) Intermittent, and

(c) Interrupted.

3. Manufacturing machinery.

4. Other manufacturing equipment’s.

ADVERTISEMENTS:

5. Special manufacturing requirement.

6. Service:

(a) Steam,

(b) Gas,

(c) Water,

(d) Air or high pressure,

(e) Electricity, and

(f) Sewerage.

Selection of Site in an Urban Area:

Advantages:

1. It is sometimes possible to find an existing building which can be used to house the factory.

2. It is easier to sell the building, if it is desired, at later stage.

3. Power and water is easily available.

4. If other factories are also situated in a big city, there will be good opportunity for discussing and having exchange of knowledge.

5. Good market for small manufacturers.

6. It is well served by railways and roads from various parts of the country so that transportation of incoming and outgoing materials is convenient and cheap.

7. It is a good labour market, where all types of labour available. Seasonal labour is also easily obtained than in a smaller centre of population, specially where unskilled labour is required.

8. Workers find easy to change job from one industry to other, if required.

9. Services of repairs and maintenance etc. can be available with existing industries.

10. Large number of government of facilities will be easily available like-Post office, Banks, Railways, Police and Fire protection.

11. Houses for workers are easily available.

12. Education for the children is not a problem.

13. Transport is easy.

Disadvantages:

1. Often sites are limited in area as sufficient land is not available and congested. Hence climate is not healthy.

2. Area being limited, it may not be possible to arrange the equipment to the best of advantages.

3. The cost of land is high and rates are liable to increase further. Land for expansion is not available at reasonable rates. The larger the city, the larger the land value.

4. Because of high standard of living, higher wages of labour will have to be paid.

5. More problems about labour and employer relations.

6. Cost of building factory will be high.

7. High taxes.

Selection of Site in a Rural Area:

Advantages:

1. The cost of land is less than in a city area and usually easier to provide space for future expansion.

2. The cheapness of land enables a more efficient layout of works to be made and gives greater freedom in selecting the most economic design for the buildings.

3. Rail or road connection can be arranged easily.

4. Labour supply may be arranged from the nearby areas or by transport from the city. Labour is cheaply available.

5. Housing can be provided by private enterprises or by local authorities.

6. Healthy surrounding and pleasant atmosphere.

7. Less labour trouble.

8. Lesser taxes and restriction.

Disadvantages:

1. Sufficient power and water facilities may not be available.

2. Enough facilities for expansion may not be available.

3. Repairing work may become difficult, because of less industry in the area.

4. Skilled workers are not easily available.

5. No recreational facilities.

6. Facilities for education to children and adults (part time courses) may not be available.

7. Government facilities may not be sufficient.

8. Transport and housing facilities may not be satisfactory.

Techniques used for Selecting Best Location:

Following are the few important techniques used to decide best location from the available alternative locations:

1. Subjective Techniques:

(a) Industry precedence,

(b) Preferential factor and

(c) Dominant factor.

2. Qualitative Techniques (Factor ranking system)

3. Semi-quantitative Techniques (Factor weight-rating system)

4. Quantitative Techniques (Operation Research Models):

(a) Break-even analysis.

(b) Economic/cost analysis, and

(c) Transportation model.

Procedure for Selecting a Site:

For selecting a site following procedure should be followed:

1. Constitution of a site selection committee.

2. Determining the company needs.

3. Deciding criteria for selection.

4. Accumulate the data.

5. Analyse the data.

6. Evaluate the alternatives.

7. Reduce number of alternatives.

8. Investigation in detail.

9. Collect and analyse further data.

Location for an Industrial Plant:

The principle of Industrial Plant Location is that the sum of manufacturing and distributing cost should be at minimum for the best location. The first two factors are related with the transportation cost. One should be clear that a plant may be located near the market as well as near the raw materials site. But in actual practice, many times, due to some other factors, it is not possible to locate an industry near the proximity of market as well as raw material.

For economical analysis these factors play an important part:

(a) Following are the factors when an undertaking is located near the raw material site:

1. When source of raw material is likely be the controlling factor.

2. When materials are bulky and of relatively low price.

3. When materials are small and of high unit price.

4. When raw materials are greatly reduced in bulk during the process of manufacture.

5. When raw materials are perishable and process makes them less perishable.

The examples are processing industries, cement, paper, meat, canning (Fruit) etc.

(b) Factors responsible for locating an industry near the market:

1. When the size or bulk of the product is more.

2. Render it more fragile.

3. More subsection about the spoilage.

Examples are shoes, furniture, glassware industries.

(c) While dealing with the economy of labour, the factors responsible are:

1. The ratio of labour cost to total manufacturing cost. If the ratio is small then this factor is not important.

2. The possibility of reduction in labour cost by using better methods or better quality of labour.

3. The type of labour required.

For example, the textile industries silk and carpet making industries, sports goods etc.

(d) Now for the economy and availability of power:

This point is similar to the raw material procurement. If power is generated from coal, then coal is a raw material. Hence still steel plants are located near the coal-mines etc.

(e) Other major factor that influences in availability of finance:

But the finance can be obtained from Government agencies. Banks etc. at any place.

(f) The following factors also influence the layout:

1. An offer of a factory site or an existing plant.

2. Subscriptions of the capital stock of the enterprise.

3. A rebate of taxes and period for which it will remain available.

4. Non-reference by local or government bodies.

5. The location should not be near the border of the country to safeguard from risk of war

6. For smooth going, political interference should not be there.

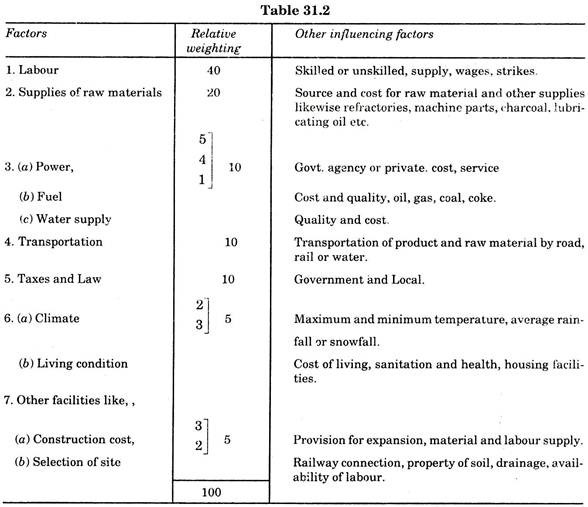

Weight-Rating Method:

Table 31.2 illustrates the weighing method for selection of local site and other influencing factors. While weighing, we establish a percentage to represent the relative importance. It is important that the better the technique for getting the weighing the better the decision. In this a questionnaire survey or group discussion may help a lot.

Before making a good decision, we should have a clear idea of objective. We should know what is the real problem, and what are the different alternatives possible for the solution. Further it is quite easy to get decision by putting numerical values, for factors which cannot ordinarily evaluate objectively.

Step 1:

Find the important factors. First of all find the factors which are considered important. For finding this, statistical analysis, questionnaire survey or other techniques may be employed. Group some of the factors in the order of importance as shown in Table 31.2.

Step 2:

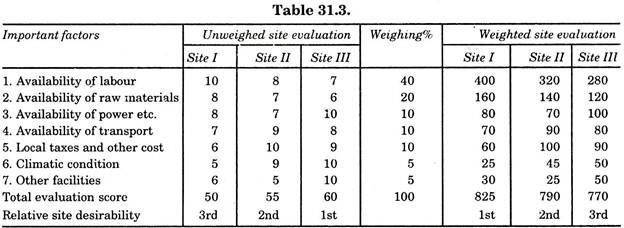

Putting the numerical values for each factor, for each alternative. This can be done at best when all the factors are considered according to the same scale of desirability.

In our example we use numbers up to 10, where 10 is the perfect in desirability. Each factor should be considered separately. There may be many methods to get these evaluations like cost studies, statistical analysis, work samplings questionnaires and all the other tools of O.R. and Industrial Engineering.

Step 3:

Weighing the factors with relative economic importance. In this we establish a percentage (of 100) to represent the relative importance. In out example we weighed the factors putting them in the middle column as shown in Table 31.3. It may be important that the better the technique for getting the weighting, the better the decision. In this, a questionnaire survey or group discussion may help a lot.

Step 4:

Calculating weighed source for alternatives. For this, multiply each un-weighed point rating with the appropriate weighted. In our example for factor 1, i.e. availability of labour for site 1, multiplying 10 by 40. Now complete the table as per Table 31.3. Finally add the weighted points to find the best site.

Now observe that how the choice is reversed by weighing. As Site I with 825 become the first choice instead of the third.

The Best Location for the Small Plant:

Following are the other points which are to be considered in addition to main factors, while considering location for small plant:

1. Select the area where producer or enterprisers have an idea about the local people, their habits, customs and needs.

2. If selection is made in a strange area, then enterpriser must personally meet the local interested people.

3. Location in rented premises is always better than purchasing. Because if change of location is sought latter, then purchased premises may cause a loss.

4. Location at the main roads or corner is best suited, if finances allow.

5. Location on side road is economical but more publicity is required to become known.

6. The first renting contract with owner must not exceed one year or so, and commitments for five or ten years must not be made until success of the projects is certain.

7. Success is not assured in any particular locality, but it can be achieved in every locality and in any location by good and careful planning.