After reading this article you will learn about:- 1. Meaning of Standard Data 2. Methods for Determining Standard Data 3. Uses 4. Advantages.

Meaning of Standard Data:

Generally large number of man hours is spent in setting the time standards by using stopwatch time study. Further management is anxious to have the time standards before the jobs are actually manufactured for cost estimating, scheduling, planning and other decision-making purposes. In this case, advantage of previous time standards already on hand can be taken.

Every operation consists of number of small work elements which are repeated in various combinations. The time values for these small work elements are established accurately, and these values are used without further time study, whenever the element occurs. These standardized timings for such elements are known as Standard Data.

For calculations of standard time, using the standard data, first step is to standardize the method (by method study). Then break the operation into small elements and note down their timings from standard data tables and then add the timing of all such elements to get the standard time of the operation.

Methods for Determining Standard Data:

ADVERTISEMENTS:

Following methods are commonly used for determining the Standard Data. These are also known as “Predetermined Motion Time Standard” (P.M.T.S.) systems.

1. Work Factor (WF) System.

2. Method Time Measurement (MTM).

3. Basic Motion Time (BMT) study.

ADVERTISEMENTS:

1. Work Factor (W.F.) System:

In this system, it is assumed that there are four major variables which affect the time required to perform a test.

These variables are:

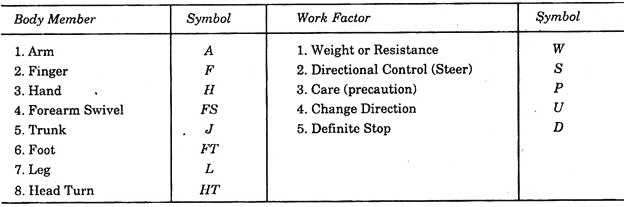

(i) Body member used, identified by exact definition like Arm, Forearm, Swivel, Trunk, Foot and Legs, Finger or Hand.

ADVERTISEMENTS:

(ii) Distance moved, measured in inches or cms.

(iii) Manual control required, measured in Work Factors. These reflects the difficulties involved. These are Definite Stop; Directional control (Steer); Care (Precautions) Change of direction.

(iv) Weight or Resistance

Work Factors Motion Time Tables:

ADVERTISEMENTS:

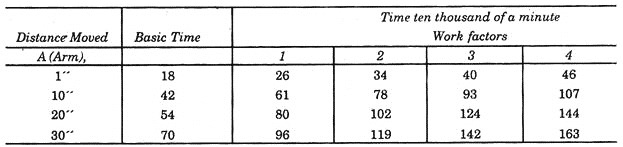

Since basic motions do not involve any work factor, the time required by different body members to move different distance is given first in the tables. Then the time needed by them after considering the work factors (in numbers) is given. Refer table below for the notations used with this system.

When a motion has been identified, according to the four major variables, the correct time value can be selected quickly from the Work Factor-Motion-Time Table (a part view is given).

In this table, values for each body member is given separately and the first column gives the distance moved, the second column gives the time for basic motion. Depending upon the number of work factors involved, time required for the motion can be noted from the corresponding column.

This table shows the values for the motion time when Arm is involved, similarly the values for other body members are also given in the table.

Recording the Analysis:

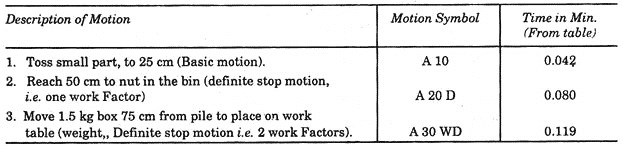

Symbols are used for recording the motion analysis. In indicating a motion, the body member is indicated first, the distance moved second and the Work Factors third.

Few example are shown as hereunder:

2. Methods Time Measurement (M.T.M.):

This system of predetermined motion time standards (P.T.M.S.) was developed from motion picture studies. In this system, each manual operation is defined into the basic motion and assigned a predetermined time standard based on nature of the motion and condition under which it is performed.

The motion time data given in the M.T.M. tables. Unit of time used in the tables is one hundred thousand of an hour (0.00001 hr.) and is referred to as one-Time Measurement Unit (TMU). Thus one T.M.U. = 0.00001 hr = 0.0006 minute.

In this system motions are classified in following categories:

ADVERTISEMENTS:

(i) Reach

(ii) Move

(iii) Turn

(iv) Grasp

(v) Position

(vi) Release load

ADVERTISEMENTS:

(vii) Disengage

(viii) Eye times

(ix) Body, leg and foot motions

1. Reach (R):

Reach is a basic element when hand or finger moves to a destination.

This varies with the following factors:

ADVERTISEMENTS:

(i) Classes of Reach:

The time to perform a reach motion is affected by the location in which object is lying.

Following are the five classes of reach:

Case A Reach: Object in fixed location.

Case B Reach: Object whose general location is known. Location may vary slightly from cycle to cycle.

Case C Reach: Object jumbled with other objects in a group.

ADVERTISEMENTS:

Case D Reach: Object is very small.

Case E Reach: Object is in indefinite position or out of the way.

(ii) The Length of a Motion is the Length of True Path.

(iii) Type of Reach:

(a) Hand is not moving either at beginning or at end.

(b) Hand is moving either at beginning or at end.

ADVERTISEMENTS:

(c) Hand is in motion both at beginning and at end.

2. Move (M):

Move is a basic element to transport an object to a destination.

Its motion time varies with the following factors:

(i) Class of Move:

It considers the condition of destination.

ADVERTISEMENTS:

(a) Case A Move: Object to against stop.

(b) Case B Move: Object to approximate location.

(c) Case C Move: Object to exact location.

(ii) Type of Move:

These are the same as those described for reach.

(iii) Length of Motion:

Same as described for reach.

(iv) Weight Factor:

Additional time is needed when an object is moved with weight (above 2 kg.). The table gives the allowances of time to be added for different weights.

3. Turn (T):

Turn is the motion employed to turn or rotate the hand, wrist and forearm either empty or loaded. The time for a turn depends upon.

(i) Weight.

(ii) Degrees turned.

The table gives the time for different slabs of weight and degrees turned. If pressure is applied while turning, an allowance given in the table is further added.

4. Grasp (G):

Grasp is the basic element employed to secure sufficient control of one or more objects with the fingers or hand to permit the performance of the next basic element required.

These elements are classified according to the size of the object and the combination of size of objects to be secured (grasped). The time for all such cases is given in the table.

5. Position (P):

Position is the basic element employed to align, orient and engage one object with another object.

The position time is affected by:

(i) Class of Fit.

(a) Loose,

(b) Close and

(c) Exact.

(ii) Symmetry.

(a) Symmetrical,

(b) Semi-symmetrical

(c) Non-symmetrical objects.

(iii) Ease of handling.

(a) Easy to handle,

(b) Difficult to handle.

6. Release Load (RL):

The release is of following two types:

(i) Normal release. Simply opening of the fingers.

(ii) Contact release. The release begins and is completed at the instant. No time is allowed in this case.

7. Disengage (D):

This is the basic element employed to break contact between one object and another object.

Time for this element is affected by the following variables:

(i) Class of Fit.

(a) Loose

(b) Close and

(c) Tight fit.

(ii) Ease in handling.

(a) Easy and

(b) Difficult to handle.

(iii) Care in handling.

8. Eye Times:

In some cases when eyes direct the hands or body movements, eye time must be considered.

There are two types of eye times:

(i) Eye Travel Time (E.T.):

This varies directly with distance between the points from and to which the eye travels and inversely with the perpendicular distance from eye to the line of travel.

(ii) Eye Focus Time (E.F.):

It is the time required to focus the eyes on an object and is equal to 7.3 T.M.U.

9. Body, Leg and Foot Motions:

The table gives the time required for the movement of different members of the body, leg and foot.

Recording the Analysis based on M.T.M. Study:

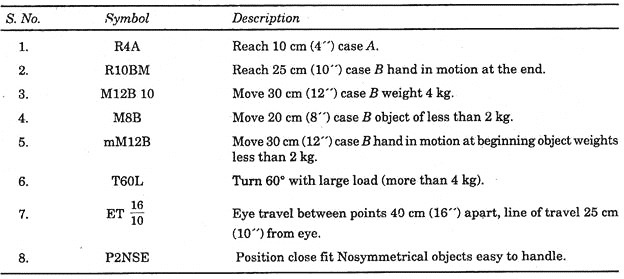

To find out the time required for an operation, break down it into elements. Each element is then identified and recorded in symbols. The M.T.M. tables are consulted to get the time values for each element.

The summation of time values for all the elements of operation gives the time required for performing that operation. Some of the symbols and their description is given hereunder to facilitate the students to understand as to how these are recorded.

3. Basic Motion Time (BMT) Study:

Following factors are taken into consideration for Basic Motion Time Study:

1. Class of motion.

2. The distance moved.

3. Visual attention.

4. Amount of force needed in handling the weight.

5. Simultaneous performance of two motions.

(i) Class of Motion:

Motions are classified as:

(a) Class A Motion: Stoppage without muscular control has lowest time values.

(b) Class B Motion: Stoppage by the use of force, needs more time than that of A.

(c) Class C Motion: Use of muscular control both to slow down the motion and to end it in grasping or placing actions.

(ii) In the table, time for each class of motion for different distances is given.

(iii) Visual Attention:

The time to perform a motion is also affected by the fact whether or not eye moves with the hand or arm. This requires slightly more time (given in the table for B.M.T.) in the class B and C, motions for travelling the same distances.

(iv) Precision required in Grasping or Positioning:

When a motion ends grasping a small object or in placing an object in exact location, a certain degree of precision is required depending upon the tolerance allowed in grasping or positioning. The B.M.T. table gives the time required in moving different distances for different tolerances.

(v) Force Factors:

Whenever a heavy weight is handled, time allowance is added. The allowances of time are given for different distances, depending upon the amount of force. These values are available in B.M.T. tables.

(vi) Simultaneous Motions:

The time for reaches and moves are affected by visual attention, eye travel, eye focus etc. The time is to be added for such simultaneous motions (also given in B.M.T. tables).

Uses of Standard Data:

1. Standard data helps in determining in advance that how long it will take to perform an operation in the shop.

2. It helps in comparing two methods and determining best method.

3. Evaluating proposed methods in advance of actual production.

4. Helps in estimating the time required and labour cost.

5. For checking standards established by time study.

Advantages of Standard Data:

1. Standard time can be found even when the product is not being manufactured.

2. Provides a basis for decision making, budgeting estimating etc.

3. Various time study persons can arrive at identical time standards for given method.

4. There can be no dispute about partiality or incorrectness of time study.

5. Economical than the time study by a stop-watch method.

6. Rating or efficiency of the operator can be determined correctly.