After reading this article you will learn about value analysis as the best cost reduction technique:- 1. Definition of Value Analysis 2. Types of Values 3. Functions of a Product in Value Analysis 4. Steps 5. Un-Necessary Costs and Value Analysis 6. Value and Cost 6. Team Approach 7. Objectives 8. Stages 9. Requirements of a Product 10. Questionnaire 11. Advantages.

Definition of Value Analysis:

Value Analysis is a tool of management which attempts the question of saving cost from the point of view of, ‘Value’ or in other words the main aim is to study the relationship between the design function and cost of a part, keeping in view to reduce part and cost through change in design, modification in specification of the material used by changing the source of supply and so on. The Value Engineering is also known as value analysis.

Value engineering identifies the areas of excessive or unnecessary expenses and attempts to improve the value of the product. It provides the base for better performance at a lower cost while reducing neither necessary quality, reliability nor maintainability.

Value Analysis is a technique of cost reduction based on systematic and organised examination of every item of cost which goes into the manufacture of the industrial product in terms of the value or customer satisfaction it adds to the product.

ADVERTISEMENTS:

Another definition of Value Analysis is “the systematic examination of all factors which contribute to the cost of a product, part or a material with the object of uncovering these possibilities of cost reduction which will not in any way reduce the quality, performance or any other attribute of the product which is sought by the customer.”

Value Analysis means the organised and exhaustively critical study of a product in terms of the design, functions and costs with the object of cost reduction.

Types of Values:

1. Cost Value:

It is the cost of manufacturing a product or component.

ADVERTISEMENTS:

2. Use Value:

It considers work done, functions performed or service rendered and efficiency/effectiveness of the product.

3. Esteem Value:

It involves the qualities and appearance of the product which attracts persons and creates a desire in them to posses the product.

ADVERTISEMENTS:

4. Exchange Value:

It considers the properties or qualities which will remain attractive enough to other people to permit market resale in the future.

Maximum value is obtained when essential function is achieved for minimum cost.

This statement can be expressed mathematically as follows:

ADVERTISEMENTS:

Vmax = F/ Cmin

where, Vmax = Maximum value, F = Functions, Cmin = Minimum cost

Functions of a Product in Value Analysis:

Functions of a product can be classified into following two categories:

1. Basic (or Primary) Functions:

ADVERTISEMENTS:

These are the functions without which the product would virtually lose all of its value, and in some cases even its identity. For example, if lead is removed from an ordinary wooden lead pencil, it would not only eliminate its basic function of pencil but will leave us with not more than a stick.

2. Secondary Functions:

These functions support the basic functions, although they may or may not be essential functions. For example, pencil without lead may still remain the esteem value by just being seen in the pocket.

Steps in Value Analysis Approach:

Sequence of steps for systematic approach of value analysis is:

ADVERTISEMENTS:

1. Orientation:

Familiarization with needs, specifications and customer desire.

2. Information:

All those facts which have bearing on the problem should be gathered.

ADVERTISEMENTS:

A typical list of information gathered is given hereunder:

a. Engineering information

b. Procurement information

c. Reliability

d. Materials information

e. Cost information

ADVERTISEMENTS:

f. Tooling

g. Manufacturing information

h. Quality control—rejection, tolerance.

i. Customers experience

j. Packaging and preservation

k. Testing

ADVERTISEMENTS:

l. Scheduling

3. Creativity:

Use of imagination and brain storming. Adopt the process of blast, create and then refine.

4. Evaluation (Analysis):

Estimate value of ideas and explore best.

5. Planning:

ADVERTISEMENTS:

After selecting few alternatives or combination of alternatives, each of them investigated thoroughly. On the basis of final outcome, detailed planning is carried out and a report is prepared for approval.

6. Execution (Implementation):

After approval of the proposals, its recommendations are implemented. Value engineers are expected to see that the approved recommendations are implemented and hindrances, if any can be sorted out.

Un-Necessary Costs and Value Analysis:

Un-necessary costs are those costs which neither contributes to function nor the appearance of the product. Value engineering/analysis attacks un-necessary costs to overcome or minimize them.

Some of the important reasons for such costs are:

1. Poor design of the product.

ADVERTISEMENTS:

2. Over design of the product by providing it with features that the user just does not use.

3. Unrealistic or too tight specifications.

4. Lack of standardization.

5. Advances in technology not considered, and old practices continued,

6. New cheaper and better sources not considered.

7. Lack of production control.

ADVERTISEMENTS:

8. Non-consideration of changed circumstances.

9. Inability to utilize specialist knowledge/available talent.

10. Wrong belief, habits and attitudes.

Value and Cost:

Normally selling price depends upon the benefit which the customers expect to drive by using the product. This benefit is translated by the customer in terms of money which he can pay or in other words, this is the value which the customer places on the article for its purchase.

This amount is entirely based on the wishes of the customer and has nothing to do with the money spent on producing the article. In some products, we usually observe that, price paid by the customer is very high even if the cost of production is small. The reason behind this is that he is very anxious to purchase it and has rated its value very high.

Thus it is necessary for the manufacturer to incur costs in such a way so as to get good response from the customers and the product will be appreciated by them. So as to ascertain the value of the product, the businessmen make the systematic efforts. The process of making the systematic efforts to evaluate the value of the product is known as ‘value analysis’.

In the manufacture of industrial products cost is incurred to create value, costs and values have input-output relationships. The scope to optimise the input of costs in order to produce a given set of values is always there. Value is what the product is worth to the customer or user.

Value differs both from price and cost. It can be defined as the cost proportionate to the utility, i.e.

Value = Utility/Cost

Thus the value of a product can he increased either by increasing its utility with the same cost or by decreasing its cost for the same utility. Users have different concepts of value depending upon time, place and availability of substitute items. Value is adjudged by cost value, use value, esteem value and exchange (re-sale) value.

The price at which the product sells or can sell on the market is a measure of its value to the customer or user.

Cost comprises of the:

(i) Money value represented by the material used to make the product,

(ii) Wages of the workers and

(iii) Other indirect costs attributable to its manufacture.

The excess of value or market price over the costs incurred in producing the product represents the margin of profit of the manufacturer. In order to make his product more profitable, the manufacturer should make a constant search for reducing the manufacturing costs.

Reduced manufacturing costs means one or more of the following advantages:

(i) Increase the margin of profit.

(ii) Reduce the loss.

(iii) Enable a reduction in selling price and thus achieve a greater demand for the product.

Customer or user pays the assigned price for the product because he considers the satisfaction derived from its use worth that price. He is generally unconcerned about what it costs the manufacturer to produce the product.

Team Approach for Value Analysis:

Value Analysis requires the cooperation of all the functional deptts in an enterprise. As all deliberations must be based on the ultimate satisfaction which the customer wants from the product, the sales and market research deptt. should be intimately connected with value analysis exercises.

The design deptt. and engg. deptt. which translates the Customer requirements into the physical embodiment of the product must also be intimately concerned as they alone would be in a position to know as to why certain parts with certain properties must be assembled to make the product.

As a major portion of the product cost is accountable by materials, the purchase deptt. which translates the design into reality and the costing deptt. which possesses the factual data about the different cost elements as also their interaction with the others which must necessarily be associated with Value Analysis.

This organised exercise is unlikely to succeed without the enlightened cooperation from all the functional areas. The team must be consisting of senior representatives of the above 5 functional deptts and they should possess special expertise in their own area which they represent so as to enable to influence the changes consequent to the recommendations of the Value Analysis team.

In large enterprises, Value Analysis should be a full time job for the team members. The Value Analysis team must have a position directly reporting to the top management. It is only, when an enlightened support from the top is assured than only the Value Analysis team will be able to implement its suggestions to the advantage of the enterprise.

Value Analysis team must keep an open mind to any suggestion, and all the suggestions should be noted down in writing and should not be rejected without consideration even if they appear prima facie unworkable.

Subcontractors and suppliers of material can come forward with reliable suggestions as regards alternative materials and their advice must be explored. Representatives of other deptts like those from the inspection, packing, shipping and store keeping can be associated when points pertaining to their specialised areas being discussed.

The actual explorations in cost reduction are based on the familiar method of questioning.

Following are these questions:

1. Can the part be eliminated?

2. Can you combine it with other parts?

3. Can you separate it into simpler parts?

4. Can you use a standard part? Generally standard parts are economical.

5. Can you use standard materials?

6. Can you use cheap materials? Cheaper materials need not always mean inferior materials.

7. Can you use less materials? There is scope for considerable saving in materials, particularly in sheet and plate work by preplanning the jobs.

8. Can you buy more cheaply?

9. Can you reduce rejects?

10. Can you ease limits? Unnecessary tight tolerances are costly to obtain and many times, they serve no useful purpose.

11. Can you save on finish? Critical examination often reveals possibilities of saving on surface finish, which includes, paintings, electroplating etc.

12. Can you use better methods? This question is particularly important for parts having high labour cost content.

13. Can you reduce the risk of error? Could the reliability of the process be improved.

14. Can you do anything else? Any other possibility of cost reduction in the peculiar circumstances of the best-usage may occur to the team.

Objectives of Value Analysis:

(i) To simplify the product

(ii) To use cheaper and better material

(iii) To use efficient and economical process

(iv) To reduce the cost of the product

(v) To improve the product design

(vi) To increase the utility of the product

(vii) To increase the profits.

Stages in Value Analysis:

Value analysis is carried out in the following stages:

1. What the Customer Wants:

In first stage customer’s requirements are recognised.

2. Finding Out the Best Method of Performing the Work to be Done:

Full use should be made of modern knowledge relating to production. Standardisation, simplification, work study, operation research, network analysis and other techniques should be employed to determine the most economic methods.

3. To have the ‘appropriate cost’ for the ‘appropriate performance’, i.e. to have the correct relationship between cost and performance.

4. Search for better ways of performing work and consider the functional use of each part of a product. The vital parts of value analysis are to eliminate the unnecessary function.

Requirements of a Product in Value Analysis:

Generally there are two requirements, namely functional or aesthetic, i.e. a product should be useful and should be pleasing in appearance.

Thus Value Engineers look them in the following ways:

1. Use:

It is the function for which the part is manufactured. For example, what is a pen supposed to do? The answer is that it should write and hold ink.

2. Esteem:

Actually this is something wider than the aesthetic side of design. The fact that a product is pleasing to look at, may induce people to buy but there are other factors. In short, the esteem aspect is concerned with getting the customer to buy.

For example, if the pen has gold plated body or other features, the customer is tempted to purchase more readily.

When value analysis is done, then it is clear that the use function cannot be avoided because it is a main function. But it is not necessary in the case of esteem function. Any benefit added on to a product, over and above those required to meet the use function, must add to the cost causing a higher price.

When analysing, it is essential to consider how much be added in order to sell the part. The esteem function cannot be eliminated altogether, but it should not be over emphasised. Now suppose the cost of gold plated pen is Rs.1000.

This cost is further divided as:

Use = Rs.15

Esteem = Rs.985

Now the question is whether Rs.985 is justified for esteem purpose. Do the additional features add to the value? This matter is closely related with the profit making.

The reasonable price of a product can be obtained by comparing with a competitive product. When this comparison is done the possibility of substitution is examined, e.g. whether a pen with a plastic body? Can the method of filling be simplified? Does the cap have to be made of expensive material and so on?

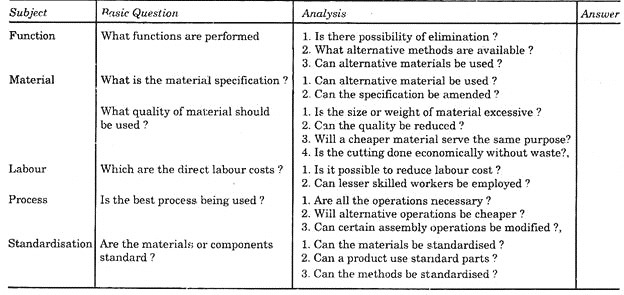

Value Analysis Questionnaire:

Advantages of Value Analysis:

There are many advantages beside the normal advantages of cost reduction-lower cost, lower prices and higher profits.

Further, the following advantages may be possible when value analysis is employed in the business:

1. The most suitable products are manufactured because a careful study is made to determine the desirable feature of each product in terms of customer’s requirement.

2. Each product should be manufactured at the lowest possible cost because special attention is paid for simplification, standardisation and improved methods of production.

3. Quality is maintained at desired level because there is no question to reduce cost at the expense of quality.

4. Value Engineering is based on the principle that management effectiveness can be measured in terms of cost saving. Any saving in cost is treated as increase in efficiency.

5. The constant search for improvement will lead to greater all-round efficiency.

6. Suggestion box method may be employed and any idea can be looked into by the Value Engineers.

7. Easy to repair or replace any part of the product.

8. Lighter in weight.

9. Easy in packaging to protect the product till it reaches to the user.