The most common method to find out how much to order is Economic Order Quantity (EOQ).

The economic lot size of an order depends upon two types of costs:

i. Inventory carrying costs and

ii. Procurement or set up costs.

ADVERTISEMENTS:

EQO gives the order level where total costs i.e., inventory carrying and procurement costs are minimum.

EOQ formula is based on certain assumptions:

i. Demand for the product is known and constant.

ii. Lead time is known and constant.

ADVERTISEMENTS:

iii. The receipt of inventory is instantaneous.

iv. Quantity discounts are not availed.

v. Stock outs and shortages are not considered.

Let Q be the Economic Order Quantity (EOQ), R be the demand per unit time in units,

ADVERTISEMENTS:

C3 be the procurement cost or set up cost per order,

C1 be the stock holding or inventory carrying cost per unit item per unit time.

Total Annual Inventory Cost:

= Total Ordering Cost + Total Inventory Carrying Cost … (1)

ADVERTISEMENTS:

Total Ordering Cost:

Total Inventory Carrying Cost:

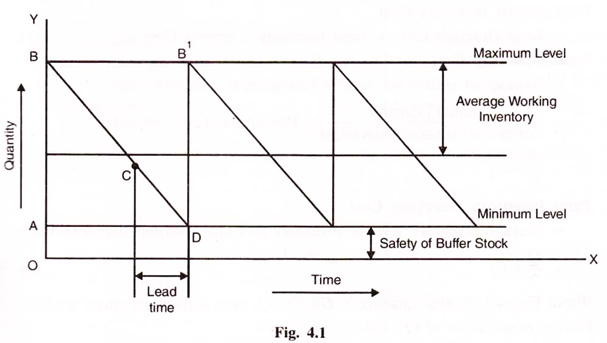

(From Fig. 4.1, if total quantity is OB i.e., Q, then average inventory=Q/2)

Putting expressions of (2) ad (3) in (1)

The objective is to determine the quantity to order which minimizes the total annual inventory cost.

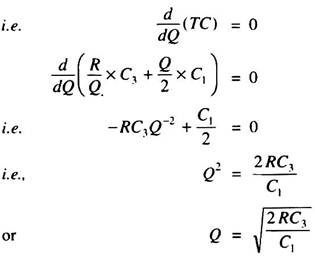

So to minimize the total cost, differentiate Total Cost (TC) w.r.t. Q and equate to zero.

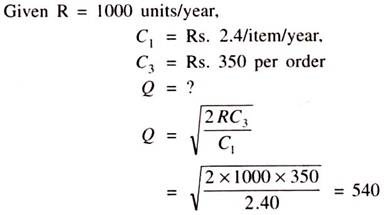

Example 1:

A dealer has to supply 1000 units of a product per year to his customer. The inventory holding cost is Rs.2.40 per unit per year and ordering cost per order is Rs.350. Determine EOQ.

Solution:

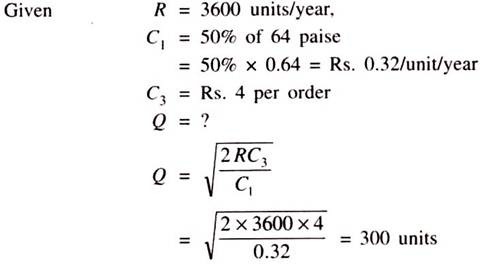

Example 2:

Given the annual consumption of material is 3600 units, ordering costs are Rs.4 per order. The unit price of material is 64 paise and storage costs are 50% per annum of stock value. Find the economic order quantity in units.

ADVERTISEMENTS:

Solution: