Here is an essay on ‘Plant Maintenance’ for class 11 and 12. Find paragraphs, long and short essays on ‘Plant Maintenance’ especially written for school and management students.

Essay on Plant Maintenance

Essay Contents:

- Essay on the Meaning of Plant Maintenance

- Essay on the Necessity of Plant Maintenance

- Essay on the Objectives of Plant Maintenance

- Essay on the Categories of Maintenance

- Essay on the Functions of Maintenance Management

- Essay on the Types of Plant Maintenance

- Essay on the Advantages and Limitations of Plant Maintenance

- Essay on the Selection of Optimum Maintenance Program

- Essay on the Measurement of Maintenance Work

- Essay on the Organisational Aspects of Plant Maintenance

- Essay on the Recent Developments in Plant Maintenance

Essay # 1. Meaning of Plant Maintenance:

Plant implies all physical means of production in a manufacturing system. These can be machines, tools, fixtures, land, buildings, office furniture, water, sewer, plumbing, temperature control systems and other facilities.

ADVERTISEMENTS:

These facilities are subject to deterioration due to their use and exposure to environmental conditions. This process of deterioration, if not checked or rectified or reconditioned may make these facilities unserviceable after some time.

This is done through the process of Maintenance. Thus Maintenance means to maintain the facilities in a system up to some desired level of efficiency some measure of performance i.e. to keep assets in a satisfactory condition or to restore these to that condition. Maintenance ensures condition of the facilities such that it permits un- interrupted implementation of plans requiring their use.

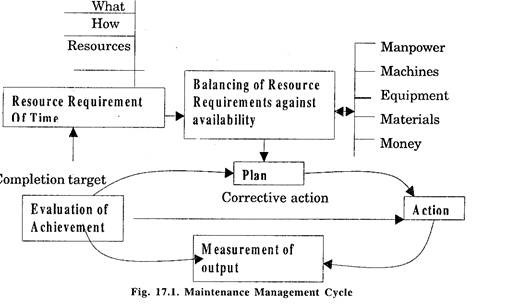

Maintenance management is concerned with planning and controlling Routine, Planned and Preventive maintenance activities of an organisation. Thorough streamlining of maintenance work is essential before an attempt is made to set standards. Irrespective of the nature and size of manufacturing systems, the following diagram describes the components of Maintenance Management cycle.

Essay # 2. Necessity of Plant Maintenance:

Maintenance activity is taken for granted in every organisation. It is last to win a word of praise if everything goes well but first to get blame if ever the production performance level shows a declining trend.

ADVERTISEMENTS:

The following are the reasons for greater emphasis on maintenance activity in modern environment of manufacturing systems:

I. Increased sophistication of equipment and higher cost of maintenance skills have caused the maintenance costs to rise at a much faster rate than production costs. Thus maintenance costs have to be considered in the course of ascertaining the most efficient operating methods.

II. The downtime or mid-work stoppage of production process these days costs much more to the organisation than it was before. This fact has given an extra dimension to maintenance needing careful planning, control and manpower allocation.

ADVERTISEMENTS:

III. Automation and complexities inherent in modern equipment’s have considerably enlarged the role of maintenance function and have made it even more essential to adopt better strategies to plan and control maintenance operations.

Essay # 3. Objectives of Plant Maintenance:

The management of maintenance activity has to concern itself with provision of un-interrupted production process at minimum cost and maximum reliability.

The following are the objectives of plant maintenance in system:

(i) To maximise the amount of time the assets will be available for use for the purpose for which these were procured.

ADVERTISEMENTS:

(ii) To preserve the value of assets by reducing the rate at which they deteriorate e.g. periodic removal of rust from the hull of a ship and repainting the areas involved preserves its value.

(iii) To perform the maintenance activities in’ a most economical manner.

(iv) To plan and schedule maintenance work so as to anticipate and prevent interruptions in operations.

(v) To perform the activities of inspection, adjustments, repairs, replacements and operation of the shops performing the various jobs.

Essay # 4. Categories of Maintenance:

ADVERTISEMENTS:

The nature and degree of maintenance efforts as well as the attention required for any facility of the system depends on its importance.

The importance can be assessed in terms of costs, disruption and hazards to safety of employees. The categorization of various plant facilities in terms of their importance would be helpful in directing the attention required by a machine. It would also help in scheduling of jobs to provide a certain element of flexibility.

Factors Affecting Categorisation:

The importance of any plant facility can be judged in terms of the following aspects:

ADVERTISEMENTS:

A. Production:

(i) Availability and type of the alternative to the facility under consideration.

(ii) Percent utilisation of the facility.

(iii) The nature of influence on production programme in the event of breakdown.

ADVERTISEMENTS:

B. Quality:

(i) The extent of quality-work done on the machine.

(ii) Performance level in terms of projection of defectives produced.

(iii) Losses due to manufacture of a sub-standard quality product.

C. Safety:

This can be judged in terms of injury that can be inflicted on the operator or surrounding workers.

ADVERTISEMENTS:

D. Maintenance:

(i) Annual cost of down time

(ii) Annual cost of repairs.

(iii) Ease in procurement of spare parts.

The above four factors viz. Production, Quality, Safety and Maintenance are not equally important for categorization of facilities in an organisation. The importance level of each factor vary from organisation to organisation e.g. quality may be very important for a precision instrument manufacturer, safety may be more important for a plant involving lot of lifting and moving of heavy items. The importance of facilities in terms of various factors can be done by discussions with the production personnel.

Besides this, all factors will not be of equal importance for each facility. Some may be required to run almost continuously to meet the production programme of the organisation whereas some machines may not involve much cost and time to repair.

ADVERTISEMENTS:

Determination of Degrees and Location of Point Value to each Degree for Categorisation Plan:

The process of determining degrees of factors and point values of each item for categorization is meant to place the facilities in their order of importance vis- a-vis the maintenance effort required on them.

The analysis consists of following steps:

A. Prepare a list of all items/facilities used in the plant viz. machines, tools, motors, gears, compressors, electrical installations, piping network etc.

B. Analyse each item and place it in the relevant degrees for all factors involving representatives of production and maintenance departments to make the categorization objective.

The analysis may lead to put each item in one of the following categories:

ADVERTISEMENTS:

Category A: Most Important:

Needs rigid operating instructions, inspection schedules, cleaning schedules and controlled lubrication programmes. Maintenance department should give maximum attention on such items to control down-time, ensure elimination of breakdown. In case of any breakdown top-priority should be given to such machines/equipment.

Category B: Important

Requires operating instructions, inspection, cleaning and lubricating schedules. Breakdowns should be avoided. Maintenance schedule for such items can be deferred in emergency.

Category C: Less Important

Requires operating instructions as well as cleaning and lubricating schedules. The maintenance schedule can be deferred to accommodate maintenance requirement on items lying in categories A and B.

Essay # 5. Functions of Maintenance Management:

ADVERTISEMENTS:

The basic function of any maintenance activity is to maintain the facility and its equipment in a condition to meet normal operating requirements.

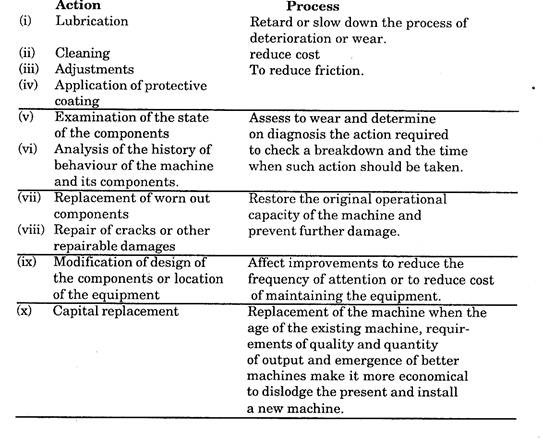

This basic function can be performed by the following activities:

I. Inspection:

Maintenance inspection involves periodic inspection of machines and equipment to ensure safe and efficient operation, making certain that equipment requiring work at specified periods receives proper attention, determination of repair feasibility and control of the quality of work accomplished by maintenance group.

Inspection implies detection of faults before they develop into breakdown of the equipment. It is an expensive strategy and has to be used selectively. It is superfluous to perform inspection upon machines that are not critical.

ADVERTISEMENTS:

II. Repair:

When any item or its component breakdowns, then the process of repairing the component or replacing the item or part of it by another item to restore the item in working order is known as Repair.

III. Overhaul:

This is another routine and regular maintenance function falling under preventive maintenance. The frequency of overhauling is far less than lubrication and inspection. Here the machine is stripped and the various parts are cleaned and oiled and critical components replaced.

IV. Lubrication:

Proper lubrication is the essence of any good maintenance system. The cause of most of the breakdowns will be traced to failure of the lubrication plan. Lubrication converts solid friction into fluid friction, thereby, reducing the gradual damage to the moving parts considerably. It prolongs the life of the equipment.

Proper lubrication means the use of right lubricant, at the right time, in right quantity and proper care of lubricants to prevent their contamination. Cleanliness of the surroundings and the containers is of utmost importance as the contaminated oil instead of reducing friction would cause wear.

V. Salvage:

Any item/equipment is classified as Salvage when it cannot be repaired or cannot be brought to desired level of performance. In that case the item is to be replaced by new one to bring back the system into operation.

Essay # 6. Types of Plant Maintenance:

Plant maintenance strategy can be broadly classified in two classes viz. Breakdown and Preventive. In breakdown maintenance, repairs are made after the equipment is out of order and it cannot perform its normal functions any longer. Then the maintenance department is called to rectify the defect.

Preventive maintenance refers to only a part of a good maintenance programme. It consists of routine actions taken in a planned manner to prevent breakdowns and to ensure operational accuracy to the extent it is economically and practically possible to do so. Preventive maintenance has been recognised as extremely important in the reduction of maintenance costs and improvement of equipment reliability.

A. Breakdown Maintenance:

This is also known as corrective maintenance. For non-critical equipment it is usually the policy to allow it to run without much routine attention. The nature, extent and time of breakdown of any equipment are a random phenomenon and can never be eliminated by preventive maintenance.

However the consequences of severe breakdowns can be forestalled considerably by repairing the equipment as expeditiously as possible by planned maintenance and provision of spares and maintenance man-hours.

Breakdown maintenance practice is economical for those equipment’s whose down-time and repair costs are less. It is administratively easier and needs comparatively small staff. The breakdown maintenance strategy can be formulated by analysing the causes of breakdown.

The causes can be:

(i) Failure to identify and replace worn-out parts

(ii) Lack of lubrication.

(iii) Inefficient or neglected cooling system

(iv) Indifference towards minor faults

(v) Too low or too high voltage

(vi) Use of sub-standard or wrong fuel

(vii) Indifference towards vibration/sound in the system

Disadvantages of Breakdown Maintenance:

(i) It results in dislocation of production process and causes excessive delays or reduction in output.

(ii) Wages are to be paid for idle time resulting in loss of profits.

(iii) Failure of machines may cause accidents leading to losses and troubles.

(iv) There may be more material wastage.

Breakdown maintenance practice cannot be employed for those equipment’s/items, which are regulated by statutory provisions like cranes, lifts, hoists etc.

In order to reduce the incidence of sudden breakdown on the performance of any system, preventive maintenance strategy is an important tool. It is carried out to eliminate an unsatisfactory condition viz. resurfacing of badly deteriorated road etc.

B. Preventive Maintenance:

All machines/equipment’s deteriorate with use and exposure.

Deterioration of machine implies change in dimensions of its various components and weakening of its members due to fatigue, impact and corrosion.

Such Deterioration is Indicated by:

i. Inability of a machine to take the specified load.

ii. Reduction in speed of the machine

iii. Deterioration in quality of the output by any machine

iv. Reduction in operational life of the machines.

This process of deterioration, if unchecked, can, not only increase the cost of production but also ultimately leads to stoppage of the machine due to breakdown of one or more parts.

Preventive maintenance is an activity, which prevents breakdowns, cut operating costs and improve output/quality of the product. It is a ‘Stitch in Time’ procedure following the principle that “Prevention is better than cure”. It involves periodic cleaning, servicing, inspection and replacement of worn-out parts.

It is periodic inspection/scheduling of facilities to uncover conditions that may lead to production breakdowns or harmful depreciation. The preventive maintenance program should be started off modestly, setting short term but reasonably attainable goals. The ideal of preventive maintenance is to make renewals before the failure of the equipment and remedy minor defects before they lead to major repairs. It is performed when the asset is still functioning viz. lubricating a fork truck, replacing worn belts, shafts, bearing, tuning of engines etc.

Objectives of Preventive Maintenance:

(i) To minimise the possibility of unanticipated production interruptions by locating or uncovering any condition which may lead to it.

(ii) To make plant equipment and machines always available and ready for use.

(iii) To maintain the value of the equipment and machinery by periodic inspection, repairs, overhauling etc.

(iv) To reduce the work content of maintenance jobs.

(v) To ensure safety of life and limbs of the workmen.

The above-mentioned objectives can be attained by adopting the following strategies:

Preventive maintenance is practiced to some extent in about 75% of all manufacturing units but every preventive maintenance programme is tailored as per the requirements of each company. Management must realise that preventive maintenance is an investment that needs extra cash as does any new plant/equipment. Preventive maintenance is discretionary and is performed at fixed intervals.

Approach to Preventive Maintenance:

Preventive maintenance refers to only a part of a good maintenance programme. It consists of routine actions taken in a planned manner to prevent breakdowns. Lubrication and inspection are the two constituents of preventive maintenance. Lubrication ensures long and safe working of the equipment without mishaps. Inspection tries to detect faults in an equipment and facility so that repairs and replacements may be undertaken before the faults assume the proportion and shape of a breakdown.

Constituents of Preventive Maintenance:

I. Lubrication:

This is used for un-keep of plant to avoid conditions of complete breakdown. Lubrication is done to remove friction from the moving parts of a component/equipment. Temperature, speed, exposure to dust, dirt, and moisture are the conditions that need to be taken into account for the proper choice of lubricant. These are used in the form of oil, grease etc.

Some important properties of lubricants are:

(i) Viscosity, which implies relative fluidity of the oil.

(ii) Flash /Fire /Pour Point: Flash point is the temperature at which any oil forms vapors upon application of flames.

(iii) Carbon contents should be as low as possible. Choice of proper lubricant and the right time to use it are most important considerations in designing lubrication policy. Besides their use of right quantity of lubricants and prevention of their contamination are other considerations.

(a) Right Lubricant:

It is generally observed that wrong lubricants are advertently or inadvertently applied because of purchase of lubricants, which does not suit the machine. It may also be due to failure to identify the right lubricant from among many kept in stores or improper mixing of various oil combinations.

The situation can be controlled by the selection of the lubricant on the advice of some lubrication expert. Codes should be used to identify the lubricants and the places where they should be applied. Different colour marking are made on the storage containers, dispensing equipment and the lubricating points on the machines.

(b) Application at the Right Time:

Failure of machines also happens when the lubricants are not applied with the desired frequency.

The remedy is:

(i) Some person should be made responsible for lubrication work. He should prepare lubrication schedules and issue lubrication instructions and maintain a control over the proper functioning of lubrication process.

(ii) A master schedule should be prepared indicating the point of the lubrication; lubricants to be used, the frequency of lubrication and the time/dates the work should be carried out.

(iii) Develop codes indicating frequencies and mark these codes at the respective lubrication points. Geometrical figures are usually used for such codes.

Control Over Quantity of Lubricants:

Excessive use of oil can be as damaging as its shortages. The quantity of lubricant per occasion should be determined on the basis of experience and measurements. The lubrication supervisor and stores manager should maintain records of consumption of each type of lubricant during a fixed time interval.

Care of Lubricants:

Contamination of lubricants by dirt, water, dust and other lubricants is an important feature of controlled lubrication. For this purpose store the lubricants in clean and dry surroundings and put a cover on the storage tank or drum. Adopt methods of transforming lubricants from storage containers to dispensing equipment that do not permit contamination. Also use one dispensing equipment for one lubricant and the equipment’s should be cleaned thoroughly before filling it with a different lubricant.

The necessity of lubrication can be assessed by lubrication surveys. These are conducted to identify shortcomings, if any, with a view to evolve a better system. The equipment used, conditions under which it operates and the lubrication points are identified.

The lubrication strategy may be designed in terms of:

(i) Its frequency

(ii) Nature of lubricants required

(iii) Care to be exercised in the handling and use of dispensing equipment and

(iv) Cleanliness of the surroundings and the containers.

II. Inspection:

The key to all good preventive maintenance programmes is Inspection. Inspection is done to check various facilities in the plant to uncover situations that may lead to production breakdowns or harmful depreciation. The basic issues involved in designing inspection strategy are what to inspect, how often to inspect, when to inspect and who to inspect.

What to Inspect In Preventive Maintenance:

A good preventive maintenance programme has to take into consideration the plant’s physical prospects viz. process equipment’s like furnaces, piping, pumps, compressors, instruments etc.; safety equipment’s, utility equipment’s like boilers, generators etc.; storage tanks, pipelines, diaphragms etc.; plant buildings and fire protection equipment.

As a rule do not inspect without ensuring:

(i) Is this a critical item?

(ii) Is stand-by equipment available in case of its failure?

(iii) Does cost of preventive maintenance exceed expense of down time and repair cost or replacement cost?

(iv) Does the normal life of the equipment with preventive maintenance exceed manufacturing need?

All these quarries can be answered:

(i) By the service manual issued by the manufacturer and

(ii) Through consultations with the operator who regularly maintains the equipment.

How often to Inspect:

The decision of how often to inspect has considerable impact on cost and saving of a preventive maintenance programme. Over inspection may lead of needless expenditure and under inspection may result in more breakdowns.

First step in assessing the best frequency of maintenance cycle is an engineering analysis of the equipment with regard to:

(i) Age, condition and value

(ii) Severity of service

(iii) Safety requirements and health hazards

(iv) Operation hours

(v) Wear and damage susceptibility

(vi) Exposure to dirt, friction, fatigue, stress, corrosion etc.

(vii) Exposure to vibrations, over-loading etc.

Once the frequency cycles are decided one has to check the results continually and modify cycles to meet operating requirements.

Some of the strategies adopted regarding when to inspect are:

(a) Whenever any unit is inspected a decision about when next to inspect is made

(b) Check new equipment more frequently.

How to Inspect?

Preventive maintenance inspections are highly repetitive and so good methods and procedures are likely to pay big dividends.

This can be done by:

(i) Study the method of inspection and servicing in terms of quality, speed and economy.

(ii) Provide better tools and test equipment.

(iii) Redesigning of equipment’s to speed up inspections.

Who should inspect?

The work can be entrusted to the members of:

(i) Production department,

(ii) Maintenance department or

(iii) To a separate division of inspectors.

The choice depends upon the conditions of the plant.

Advantages of Preventive Maintenance:

(i) Less production down time because of fewer breakdowns.

(ii) Lesser overtime payment for maintenance worker and repairs than for breakdown repairs.

(iii) Fewer large scale repairs and fewer repetitive repairs.

(iv) Fewer product rejects, less spoilage, better quality control.

(v) Lesser stand by equipment requirement thus reducing capital investment.

(vi) Better spare part control leading to minimum inventory level.

(vii) Ensures greater safety to workers.

(viii) Reduction in maintenance costs.

(ix) Lower unit cost of manufacture.

Comparison of Breakdown and Preventive Plant Maintenance:

Relationship exists between the amount of preventive maintenance which has been performed; and the amount of corrective maintenance which will be required. An increase in preventive-maintenance can be expected to reduce the frequency with which the need for corrective maintenance arises.

(i) A component which is not replaced or repaired for preventive Reasons, when it eventually malfunctions and damages other components of the asset.

(ii) The corrective maintenance cannot be planned and scheduled as systematically and efficiently as Preventive maintenance.

Preventive maintenance is a planned activity and analyst knows when it will take place, how much time it will require and what resources are required for its implementation.

For corrective maintenance the analyst would have to know the number of future breakdown, the point in time when they will occur and the nature of malfunctions. All these information’s/predictions can be based on the past maintenance records of the assets involved.

Essay # 7. Advantages and Limitations of Plant Maintenance:

Advantages:

i. Better performance with corresponding decrease in costs.

ii. Maintenance jobs are quite unpredictable in occurrence and in time. Reduction in maintenance delays can be done through planning and scheduling.

iii. Reduction in downtime of equipment/machines.

iv. Improvement in quality of the work.

v. Better supervision.

vi. Identification of training needs.

vii. Helps in introduction of incentive schemes.

Limitations:

Every work performed in maintenance department is of different type. Therefore the maintenance work cannot be standardised. The type of techniques to be used to establish a standard would depend on the size and type of industry and the complexity of the job.

Essay # 8. Selection of Optimum Maintenance Program:

The following procedure can be adopted to determine optimum maintenance strategy in a given situation:

(i) Select the alternative maintenance levels.

(ii) Determine the preventive maintenance cost that will be experienced with each of the alternatives identified in step (i).

(iii) Estimate the corrective maintenance cost that will be experienced with each level of preventive maintenance.

(iv) Find the sum of the preventive maintenance cost and the corrective maintenance cost.

(v) Select the alternative, which minimises the calculated total maintenance cost for the asset.

Essay # 9. Measurement of Maintenance Work:

The term work measurement refers to the application of a specified set of a technique to determine, in terms of time, the amount of work contained in a job etc. A number of techniques have been developed to measure work.

The choice of the technique may be made keeping in view that the time arrived at through the technique chosen is:

(a) Sufficiently accurate for the purpose for which it is to be used.

(b) Acceptable to the parties concerned i.e. workmen, supervisors and management.

(c) Attainable.

The work measurement technique in maintenance consists of following steps:

I. Analysis of Past Records:

The information from past job cards/daily diaries can be usefully analysed. The jobs are divided in two main categories viz. routine type or non-routine type. The basic criteria for placing a job in the routine category is that it occurs repeatedly, the nature of work involved is fully known and the time is not likely to vary much on repeat occurrences of the same job.

One can easily find average time value for such jobs. In the case of non-routine jobs, which do not occur frequently, the method of carrying them out is not known in detail and the time of execution for such jobs varies from situation to situation.

Analysis of such jobs involves following steps:

(i) Grouping of jobs for each trade like carpentry, electric fittings, welding etc.

(ii) Splitting jobs of each trade in terms of time ranges.

II. Time Study:

The steps involved are:

(i) Breaking the jobs into elements.

(ii) Recording the time actually taken by a worker for performing each element. Stopwatch can be used for recording this time.

(iii) Assess the effective speed of work adopted by the worker under observation comparing by actual time to a mental concept of a normal speed for that element.

(iv) Correction of observed time for variations in observed speed of work using the formula. Normal Time Observed Time x (Observed Speed/Normal speed)

(v) Assess the relaxation time required to recover from the physical and mental fatigue as percentage of normal time.

(vi) Add the relaxation time to normal time.

III. Production Study:

This is similar to time study accounting for the way a person spends his time.

IV. Analytical Estimation:

This technique is most commonly used for maintenance work. Here the job is first broken into elements and then a person who knows the job and possesses the concept, estimates the time that would be taken by a normal worker to perform each element of the jobs. Subsequently relaxation allowances are added to get the total time for the job.

V. Universal Maintenance Standard:

This technique is based on the belief of the originators that it is unrealistic to expect that every maintenance worker will do a job with exactly the same motion pattern and in exactly the same time. According to them exact method of doing the work cannot always be specified and that it is unrealistic to delegate the determination of the method to the worker himself.

The techniques consist of the development of standard work groups for each work. Each group represents a definite time range. The types of jobs that fall in a group are illustrated by a minimum of three bench mark jobs. A trained practitioner of the technique can then make a mental comparison of the work content of each new job and place it in the relevant standard work group.

VI. Basic Work Data:

The technique of basic work data has been developed by Imperial Chemical Industries limited (U.K.) and is based on simplified preventive maintenance test standards.

Here the maintenance work is divided into the following activities:

(i) Movement of the workers between work points.

(ii) Use of hand tools of different types.

(iii) Use of gauging tools.

(iv) Assemble of parts under different conditions of work for different types of fit and with or without the use of a vice.

(v) Dismantling of parts.

VII. Work Sampling:

Activity sampling is used to measure work without the use of measuring device-using sampling. The technique is mainly used to measure delays and idle time on the part of men and machines. It can also be used to estimate contingency and other allowances.

The technique is very easy to operate and the results derived are very useful in improving the study. Here the observations must be recorded at regular intervals of time and the number of observations should be fairly large. Activity sampling can be used for estimating machine idle time and delays, operators work-loads and time standards for non- repetitive jobs.

Essay # 10. Organisational Aspects of Maintenance:

The function of maintenance can be divided in two main categories: Line and staff functions.

Line function consists of lubrication, overhauling, inspections, repairs, replacements, manufacture and rectification of spares etc.

Staff function involves maintenance of engineering and other records, planning, scheduling, dispatching, ordering, evaluation and reporting.

National Productivity Council urges that the maintenance chief should have a high status. He can ensure that the machines are shut, if, his inspector advises him that this is feasible. Production and maintenance personnel should sit together in formal meetings to sort out problems and determine priorities. Maintenance staff should have occasional contacts with purchasing and accounts personnel for capital replacements.

Essay # 11. Some Recent Developments in Plant Maintenance:

A variety of management techniques are used for plant maintenance with following results:

(i) Increase in maintenance efficiency.

(ii) Reduced maintenance costs.

(iii) Improved services.

The techniques are based on Work Study methods, CPM/PERT, use of Operations Research and Computers.

Computers can prepare maintenance work orders, eliminate human error, and reduce cost of keeping record of equipment’s. Reduction in premature replacement of parts etc.