This article throws light upon the four important rules of human motions. The rules are: 1. Rules Concerning Human Body 2. Rules Concerning Work Place Layout and Material Handling 3. Rules Concerning Tools and Equipment Design 4. Rules Concerning Time Conservation.

1. Rules Concerning Human Body:

(a) Both hands should be used for productive work.

(b) Both the hands should start and finish their motions at the same time.

(c) Except for the rest period, the two hands should not be idle at one time.

ADVERTISEMENTS:

(d) Motions of hands or arms should be symmetrical, simultaneous and opposite.

(e) Motions should be simple and involve minimum number of limbs (of course depending upon the type of work). The purpose is to perform the work in the shortest duration of time and with minimum of fatigue.

(f) It is very desirable for a worker to employ momentum to assist himself where the same (momentum) is not to be overcome or conquered by his own muscular efforts.

(g) Motions should be smooth and continuous; they should not involve frequent stops and sharp directional changes.

ADVERTISEMENTS:

(h) Ballastic movements (i.e., as used in driving a nail) wherever feasible should be preferred over controlled ones because they are easy, fast and more accurate.

(i) A worker may use mechanical aids to assist him to overcome muscular effort.

(j) Work movements should be rhythmical and automatic, if possible.

2. Rules Concerning Work Place Layout and Material Handling:

(a) There should be a definite, fixed and easily accessible location for materials and tools.

ADVERTISEMENTS:

(b) As far as possible, materials, tools and other mechanical devices should be kept close to the work place.

(c) Gravity should preferably be employed for delivering materials at the work place.

(d) An assembled or final product should preferably be dropped on a conveyor (or chute) near the work place, so that gravity and not the operator delivers the job at the required place. Hands should normally not be employed for non-productive work.

(e) Tools and materials should preferably be located in the order or sequence in which they will be required for use. It reduces mental strain (on the operator) and the process becomes more or less mechanical.

ADVERTISEMENTS:

(f) Good illumination is necessary for proper seeing, fast operating and reducing accidents.

(g) In order to impart rest to some of his limbs, an operator may sometimes sit or stand while working. This necessitates a relationship between his chair height and the height of the table or work place.

(h) In order to reduce fatigue, the seating arrangement of the worker should be comfortable and adjustable.

(i) All heavy parts should be lifted by mechanical devices.

3. Rules Concerning Tools and Equipment Design:

ADVERTISEMENTS:

(a) Jigs, fixtures and foot operated devices should be employed to reduce the work load on the hands.

(b) Wherever possible, those tools should be used which can perform more than one operations. This saves a lot of time, otherwise wasted in searching and picking a number of tools.

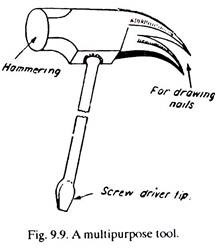

A tool shown in Fig. 9.9 can carry out three operations, namely:

(i) Hammering,

ADVERTISEMENTS:

(ii) Drawing out nails, and

(iii) Screw driving.

(c) Preferably, tools and materials should be preplaced and located near the work place. It saves the time otherwise wasted in searching and bringing the tools for doing job.

ADVERTISEMENTS:

(d) There should be maximum surface contact between the tool (handle) and the hand. It helps proper application of hand force and minimizes fatigue.

(e) Where the work is carried out by fingers (as in typing) the load distribution on-to-each finger should be as per the normal capacity of the finger.

4. Rules Concerning Time Conservation:

(a) Even temporary ceasing of work, by a man or machine should not be encouraged.

(b) Machine should not run idle. It is not desirable that (the lathe chuck holding) the job is rotating but no cut is being taken.

(c) Two or more jobs should be worked upon at the same time or two or more operations should be carried out on a job simultaneously. For example, a drill and a turning tool may simultaneously operate on a part being manufactured on a turret lathe.

(d) Number of motions involved in completing a job should be minimized.