After reading this article you will learn about the concepts and input output model of production system.

Concept of Production System:

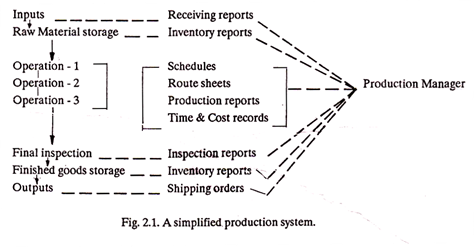

The production system is a part of a larger system – the business firm. The production system can be viewed as a framework or skeleton of activities within which the creation of value can occur. Briefly, the difference between the value of inputs and the value of outputs represents the value created through production activities. At one end of the production system are the inputs and at the other end are outputs. Connecting the inputs and outputs are a series of operations or processes, storages and inspections. Fig. 2.1 represents a simplified production system.

The concept of production system is applicable to both production of components and production of services as well. The production of any component or service can be viewed in terms of a production system. For example, the manufacture of furniture involves such inputs as wood, glue, nails, screws, paints, sand paper, saws, workers etc. After these inputs are acquired, they must be stored until ready for use.

ADVERTISEMENTS:

Then several operations, such as sawing, nailing, sanding and painting can occur through which inputs are converted into such outputs as chairs, tables, etc. After the finishing operation, a final inspection occurs. Then the outputs are held in stock rooms until they are shipped to the customers.

Examples of service industries which use production concepts are hospitals, railroads, airlines, supermarkets, automobile repair shops, etc.

Input Output Model of Production System:

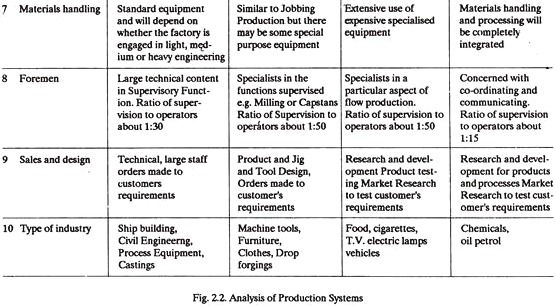

It is one of the basic models of the production system. A production system is the set of interconnected input-output elements and is made up of three component parts namely inputs, process and outputs (Fig. 2.3). A wide variety of inputs are transformed so that they give out a set of outputs. The transforming process can be complicated and the design of an actual input and output system for manufacturing may be expensive and difficult.

The efficiency of an engineering system (a machine)

= Output/Input ≤ 1, a system with output equal to input is considered to be ideal. But in a system of Production Management this definition of efficiency means utter failure and ultimately the end of the business. In economic system, the efficiency has to be greater than one – which means a state of profit. A production management system comprehends and integrates both engineering and economic criteria in its activities.