Steps involved in one Complete purchasing cycle are:- 1. Recognition of Need, Receipt and Analysis of Purchase Requisition. 2. Selection of Possible Potential Sources of Supply. 3. Making Request for Quotation. 4. Receipt and Analysis of Quotations. 5. Selection of Right Source of Supply. 6. Issuing the Purchase Order. 7. Follow-Up and Expediting the Order and Others.

Step # 1. Recognition of Need, Receipt and Analysis of Purchase Requisition:

a. Whenever a department needs an item, it is officially brought to the notice of the purchasing department.

For this purpose two procedures are followed:

(i) One involves the issuance of requisition by the using department or the stores department,

ADVERTISEMENTS:

(ii) The other involves the issuance of a bill of materials.

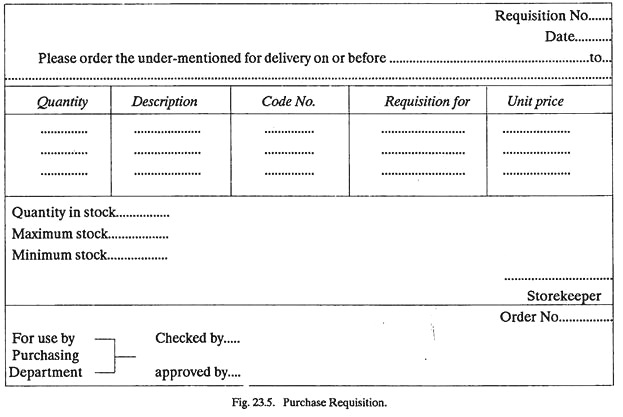

b. A purchase requisition (Fig. 23.5) forms the basis for action by the purchasing department.

A purchase requisition contains the following data:

(i) What material is required and of what quality?

ADVERTISEMENTS:

(ii) Quantity of material to be purchased.

(iii) Date by which the material is required.

(iv) Place at which the material should be delivered.

Purchase requisition is prepared in duplicate and is signed by authorized individuals only. Purchase requisition is usually routed through the stores department in order to check whether the item is available in stores.

ADVERTISEMENTS:

A bill of material is used when standard parts and small expendable tools are to be purchased. The buyer works out total material requirements from the bill of material, goes through the list of existing inventories and finally decides the net materials to be purchased.

Step # 2. Selection of Possible Potential Sources of Supply:

This process consists of selecting a fair number of vendors in accordance with established guidelines, from whom quotations will be requested. For items which are purchased frequently, the buyer usually has a few preferred suppliers from whom he purchases regularly.

For purchasing new items, reference may be made to one or more of the following from which information may be obtained:

ADVERTISEMENTS:

(a) Catalogues,

(b) Trade journals,

(c) Advertisements,

(d) Trade exhibitions and fairs, and

ADVERTISEMENTS:

(e) Trade directories (classified).

When considering a potential source of supply, the buyer should consider:

(1) Whether to purchase from local market or farther afield;

(2) Whether to buy from a single vendor or from several vendors at a time; and

ADVERTISEMENTS:

(3) Whether to purchase directly from manufacturers or through wholesalers.

Step # 3. Making Request for Quotations:

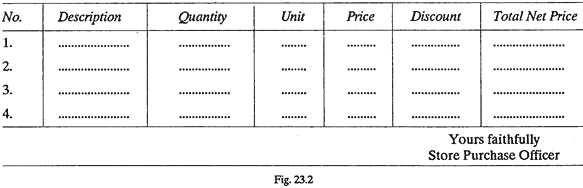

Request for quotations is made on prescribed quotation form (refer Fig.23.2) to all the selected (possible) sources of supply. The request is not a purchase order, rather it is merely an enquiry to know whether the vendor can supply the desired material by the specified date and if so, then at what rate. Quotation form has printed on it the terms and conditions under which the buyer would like to purchase the material.

Step # 4. Receipt and Analysis of Quotations:

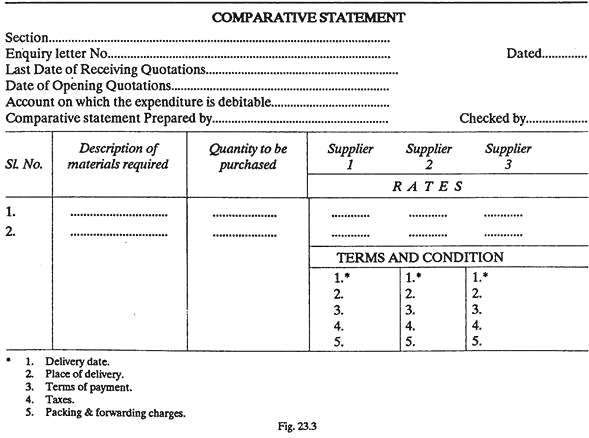

After receiving a number of quotations from different suppliers, they are studied and a comparative statement (refer to Fig. 23.3) of rates and other terms and conditions mentioned in the quotations is prepared.

Step # 5. Selection of Right Source of Supply:

The comparative statement as prepared in step (iv) above serves a good guide in selecting the right source of supply.

Other questions which might also be given a thought are:

1. Will vendor maintain quality?

2. Will vendor supply material in time?

3. Does the vendor have adequate facilities to handle the contract?

4. How far the vendor’s plant is situated? etc.

Step # 6. Issuing the Purchase Order:

ADVERTISEMENTS:

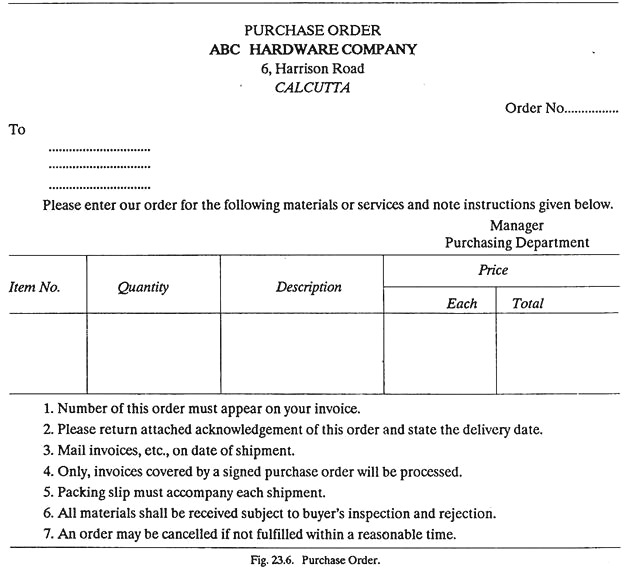

After selecting the right supplier, a purchase order (Fig. 23.6) is dispatched to him. The purchase order constitutes a legal document and it serves as the vendor’s authority to ship the materials and bill the company.

A purchase order once accepted by the vendor constitutes a contract for the delivery of the articles in accordance with the terms of purchase agreement.

The purchase order is executed in six copies:

1. Two copies go to the supplier, one he preserves, other he signs and returns.

2. One copy goes to accounts section.

ADVERTISEMENTS:

3. One copy goes to purchase service to follow-up the order.

4. One copy is sent to receiving department.

5. The last copy is kept in the files of the purchasing department.

Step # 7. Follow-Up and Expediting the Order:

After placing the order, the purchase service section maintains contact with the vendor in order to:

1. Obtain information as to the progress of the order;

2. Ensure that delivery dates will be met; and to;

ADVERTISEMENTS:

3. Take corrective actions (such as transferring some of the orders to some other supplier, change the mode of shipment, i.e., from rail road to air service etc.,) so that the materials can reach the plant as originally planned.

4. Specially designed postcards containing the following information are frequently employed for routine follow-up.

a. Purchase order Number.

b. Pre-decided delivery date.

c. Promising shipment date, etc.

Step # 8. Analysing Receiving Reports and Processing Discrepancies and Rejections:

Receiving reports are the records of what has been actually received. Receiving reports are compared with the purchase order in order to find discrepancies, i.e., variations in quantity, etc., if any.

ADVERTISEMENTS:

Discrepancies found if any during inspection as regards the quantity or quality of the received material should be promptly brought to the notice of the supplier. Before returning the material rejected during inspection at his end, it is necessary for the buyer to get the vendor’s authorization for return and replacement.

Step # 9. Checking and Approving Vendor’s Invoices for Payment:

Invoices should be checked to ensure that:

1. The correct material (in quality and quantity) has been supplied;

2. The material has been supplied at agreed prices; and

3. Agreed discounts have been given.

After confirming the above, the payment is made to the vendor for the (value of) goods received.

Step # 10. Closing Completed Orders:

ADVERTISEMENTS:

Before closing the completed orders, the file copy of the purchase order must be checked against both the receiving reports and the vendor’s invoice and a notation of this fact should be made on it. It should then be removed and stored in the file of closed orders.

Step # 11. Maintenance of Records and Files:

The final step in the purchasing procedure consists of filing the records of the transaction.